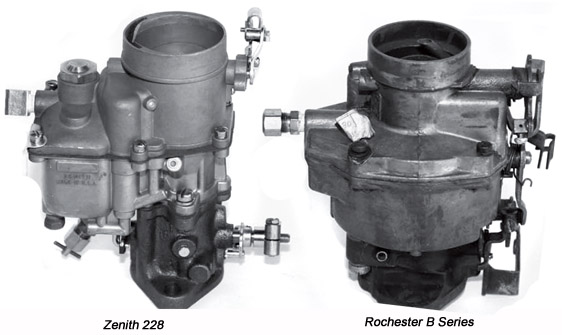

The Rochester B series carburetor originally came as a tall

version designed to have the air filter clamped to the top of the

carb. The Land Rover 'L' shaped tube clamps nicely to this

design. Starting in 1957 the B series was redesigned incorporate

a new low air horn design, to facilitate lower hood styling. The

stock Land Rover tubing from the air filter will not fit

this carb. The B series were manual choke and were standard fitment in Chevy

trucks. The BC series is the same carb but equipped with

a automatic choke and came as standard fitment to Chevy passenger

cars.

The

Rochester B series carburetor with long neck came on three sizes

of GM six cylinder engines, the 216, 235 and 261. Each size

engine used a different B series carburetor with a different size

venturi. The

216 engine is closest in size to the Land Rover four cylinder engine

and has the smallest venturi diameter. Larger venturi carbs

work less well in the off idle and mid RPM range. As near as I can tell the 216 was used on Chevy trucks up to 1953. The

235 was available on Chevy trucks 1950 through 1953 (maybe longer) and

the 261 1954 to at least 1957. I'm limited by the issue date

of the Rochester documents I examined.

You will need to reduce the size of the main jet. 50 or

52 is a good starting point if you are near sea level or 48, 49 if

you are above 5000 feet altitude. The best way to pick a main jet

is to put the car on an exhaust analyzer.

The Rochester is a simple, easy to rebuild, relatively inexpensive

carburetor that provides an increase in fuel flow over the Zenith

or Solex carbs. With a low restriction air filter, you should notice

a slight HP increase on the open highway. This will be most noticeable

on hills. Properly jetted, you should see very little fuel mileage

loss if any. In my 109 I was getting an average of 16 MPG on the

open highway (50-55 MPH). The float valve placement allows this car

to work well under off road off camber situations. The main jet

is mounted in the top cover making it immune to stirring up an

sediment in the float chamber. That is a problem with Webers.

Fitting the Rochester:

The series B Rochester is almost a direct fit to a Solex equipped

LR engine. The Zenith is turned 90 degrees to the Solex so

the base adapter will need to be removed and you will need to fiddle

with the linkage. You will need to elongate the mounting holes

at the base of the carburetor a little for a proper fit.

The early Rochester B series carburetor has a hole in the base. This

is the direct manifold vacuum passage which operates the

sustained power system. This system provides additional fuel for

sustained high speed operation or increased road load power It

also helps with fuel economy. The bottom line here is that you

do not want to cover this hole with a gasket. Rochester

base gaskets have a cut out slot going between this hole and the

throat of the carb at the base. The Land Rover carb base gasket

does not. Use the Rochester base gasket, NOT the LR carb base gasket. It helps if you can provide more than a single gasket height between the carb base and the intake manifold for air flow.

For many applications Chevy placed a 1/4 inch thick fiber gasket between the carburettor and intake manifold to minimize heat soak or vapor lock on hot days. Most auto parts stores used to carry the 1/4 inch thick fiber gasket. Depending upon the 1/4 inch spacer's construction you may need to add a thin gasket above and below the spacer gasket (keeping those slots open).

Here is an internet source for the spacer gasket: https://quadrajets.com/base-gasket-rochester-3982946-6270073-p-1023.htmlpart

As an alternative you can stack 3 or 4 Rochester base gaskets together.

I mounted a little nylon cable clamp to one of the screws securing

the top plate of the carb to clamp the choke cable

housing in place. From experience I have found that metal vacuum tubing between

the carb and distributor vibrates and breaks when you drive wash

board surfaces. I switched to a rubber tube vacuum line to solve

this problem. The carb is set up for a threaded tubing vacuum advance line.

I ended up running about an inch of copper tubing from the carb then added the rubber vacuum line. Fittings on most if not all versions are 1/8" NPT.

The stock air cleaner does not flow enough air for the Rochester

to reach its maximum HP potential. If you wish to see extra HP

from the Rochester you will need an air cleaner with a higher flow

rate such as a K&N, or aftermarket filter with a paper element.

However the K&N does not filter well enough for sustained use

in a high dust environment and paper filters become clogged quickly

under those conditions. I recommend a high flow paper element filter or K&N be used

for pavement driving and that you switch back to the stock oil

bath air cleaner when driving off the pavement. If you leave the

stock filter in place it doesn't take long to make the switch and

your engine will stay healthy longer.

Maintenance

Carb rebuild kits are inexpensive and readily available at almost

every auto parts store. Carburetor specialty stores generally have

a selection of main jets for this carburetor. There is a pressure valve inside the carburetor body that consists

of a steel ball and a spring. There is a metal rod across the top

of the opening to keep the parts in place. A rebuild kit comes with

a new ball and spring. Be advised that the spring rate is different

than the original and replacing it can cause problems. Leave this

pressure valve alone if you can when rebuilding the carburetor If

you need to open up the passage reuse the old spring.

Float level (base of carb top to bottom of float, carb top upside down) = 1-9/32" using Rochester float gauge M-250. Bend float arms to adjust.

Float drop (base of carb to to bottom of float, carb top right side up) = 1-3/4" using Rochester gauge BT-93. Bend float tab at float valve to adjust.

The original Rochester factory part numbers for the gasket kit

is 7004085 and 7009311 for the repair kit. A current rebuild part number is 7004363.

The old car manual project has the manual for the B series Rochesters used on the 216 engine

The service manual for early B series Rochesters is also on line.

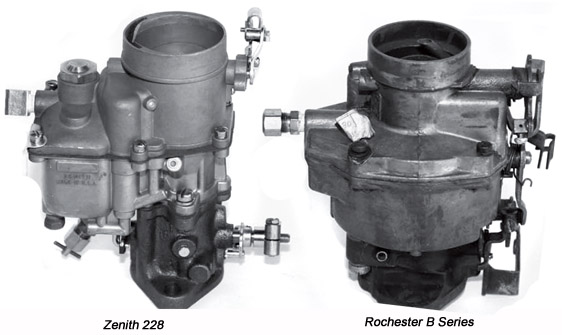

The Zenith Model 228 is a modern version of the Zenith Model 28 carburetor which was used on GMC 6-cylinder truck motors from 1946 until 1962. These engines came with either the Rochester B series or the Zenith 28 carburetor. The Zenith Model 228 is a current production carburetor made in Bristol, Virginia. The Model 228 has a manual choke, comes in four throttle bore sizes and features interchangeable venturi sleeves. For ease of tuning, Zenith offers a wide range of jet and power valve sizes. It comes with throttle levers and air filter adapter that allow it to cover most of the original one barrel carburetors.

The Zenith 228 has a 1/8th pipe thread inlet and the same base fitting as the Rochester B series above.

228 specifications from the Zenith web site

REBELRODZ MAGAZINE - December 2009 issue