|

During

the month of July 1999 the Green Rover said good-bye to being

passed

uphill by old VW vans and was converted to a Ford 302 V8. The design

and fabrication was done by Timm Cooper, then of Portland

Oregon with me assisting on disassembly and reassembly. I

have found that a basically stock 302 has plenty of power to do

anything I ask of my 5,600 pound 109. I never gear down on highway

grades, can easily climb any slope that my tyres can grip and go

through deep sand without bogging to a stop. A stock 302

from a 1970 Bronco has 8.6:1 compression (regular grade petrol),

205 HP at 4600 RPM, 242 lb Ft torque at 1200 RPM (vs. Stock LR 70HP at 4000 RPM and 120 lb ft at 2200 RPM). In 2018 the tired engine got replaced by a 1993 Bronco 5.0. I mated it to my 1993 Mustang EFI system and found myself learning a lot about engine differences.

This web page was originally written as a long

single page discussion on how to do a V8 conversion in a Series

Land Rover. I

have split out the information to several web pages and added additional

information to each. This page deals with choosing and setting

up a small block Ford V8 for a Series Land Rover and as such only

contains part of what you should know for a successful conversion.

It is not a stand alone how-to web page but part of a how-to group

of pages.

Never forget that an engine power upgrade means you need to upgrade your gearbox and at least rear axles. Not doing so is a case of deliberate gearbox and 10 spline axle murder. Punishable by a non-mobile truck and loss of lots of cash.

Introduction

to Series Land Rover conversions

discusses conversions in general and what a conversion usually

entails. It also provides suggestions as to which conversions

would be easiest for different models of Series Land Rover. You

will also find links to suppliers of adapters and drive train

upgrades that you will need.

Thoughts

about V8 conversions & body prep for the engine provides

a comparison between Ford & Chevy V8 conversions. The

page provides detailed descriptions of frame and body modifications

needed to fit a small block V8 into a four cylinder Land Rover

engine bay. There is also a discussion on radiators along

with some helpful charts for exhaust pipe diameters and intake

air flow.

Gearboxes

commonly used with V8 conversions deals with the various gearboxes

commonly used in conversions and has gear ratio numbers that you

will need in order to make the best choices for your new engine. This

page is one of a group of three dealing with gearboxes.

A high percentage of series V8 or V6 conversions seem to be poorly

done by good people who are a little unclear of what needs to

be done or what works. I'm no expert but what I have learned may

help someone who wants to design and fabricate their own conversion.

Here is a quick recap: The stock gearbox is not strong enough to

handle a modern V8, nor are the rear axles. A Series transfercase

has plenty of strength. Dana-18 and some Toyota transfer

cases can also be used. The rear axle should as a minimum,

be upgraded to a Salisbury 24 spline unit (Dana 60 built under

license) or stronger. You

can get by with a 10 spline front, but a 24 spline or stronger

is recommended.

The small block Ford V8

In 1962 Ford introduced a new lightweight 90 degree 221 cu in

that was to grow into the 302 and 351 engines. There were several

versions of this engine. The most common version was named after

the city in which the engines were built, Windsor, Ontario. The

302 was introduced in 1968 and was in production through 2000 (2002 for Ford Australia).

The 351 was in production from 1969 through 1996. Most

of the after market performance accessories are made to fit the

Windsor engines, also known as the 302W (5.0L) or the 351W, (5.8L).

These engines underwent a large number of changes over the years

to comply with ever stricter emissions requirements and evolving

technologies. Early emissions technology required casting changes,

detuning, retarding the timing and an array of vacuum controlled

devices which made the engine progressively less reliable and reduced

power. It wasn't until the vacuum control systems started being

replaced by computer controlled systems that the small block engines

started becoming more reliable and more powerful. In 1984 the carburetor

was largely replaced by throttle body fuel injection. Starting in 1982 the sequential HO EFI was introduced on high performance models of Mustang. This system was improved over the years with 1993 Mustang EFI considered the best and easiest to install version.

A number of changes were made to the engine over its 32 years of production which you should be aware of when selecting and engine or building up an engine:

- The early 302 had a cast iron crank, flat tappet cam and 9.5:1 compression. It came with either s 2 barrel or 4 barrel carburetor.

- 1970 the push rod and rocker arm geometry was changed, the water pump was changed to produce cross flow in th radiator and the harmonic dampener was changed. So if you have a pre-1970 block you need to be aware of those changes.

- in 1972 the compression was reduced to 9.0:1 and possibly smaller diameter head cooling passages to make the engine run hotter. Heads from 72 though about 1983 are best to be avoided.

- Starting 1982 sequential EFI with HO timing (same as 351) became available on high performance Mustangs. Starting 1983 a non-HO timed EFI became available across the 302 line.

- 1985 THE BLOCK WAS REVISED. BLOCK COMPONENTS CAN NOT BEUSED BETWEEN THESE ENGINES AND EARLIER ENGINES. The revisions include: roller camshaft, steel crank with closer tolerances, different timing chain cover that uses a reverse direction water pump and serpentine belt. and for most models an oil pan that has its sump in the middle.

- In 1986 a sequential EFI system was introduced for the Mustang. Other engines continued to use the older EFI system with original cam timing. The sequential EFI system was improved over time. The 1993 Mustang EFI system is generally considered to be the best of the OBD1 Ford EFI systems.

- In 1994 some changes were made. I don't know what but many aftermarket accessories do not fit 1994 and newer engines.

- In 1996 the country switched over to OBD2, distributors were eliminated, and the ODB2 5.0 engines were starting to be phased out with the last used in 2000.

If your state requires newer engines to pass emissions testing you are probably best off with a 1971 or earlier engine block. You can keep it carburettered or convert it to EFI for better power and fuel economy. If it doesn't matter which year you choose a post 1985 engine would be a good choice.

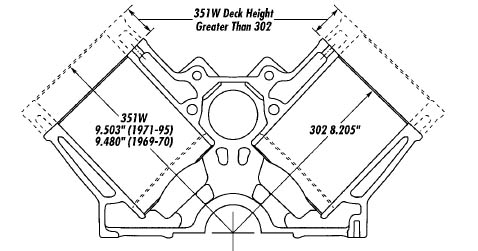

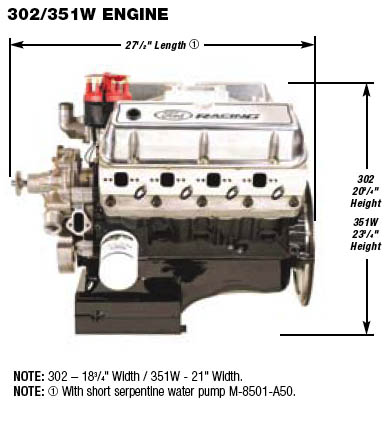

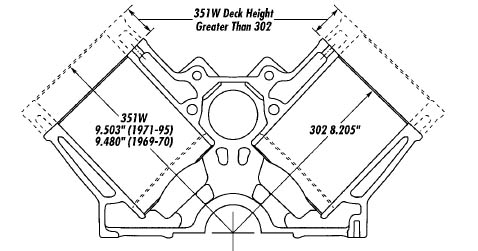

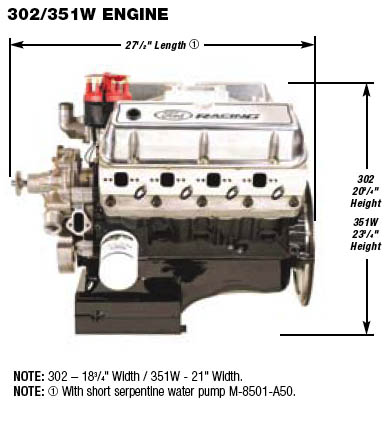

302 or 351?

The 351 is basically a stroked 302. It didn't receive the changes that the 302 underwent over time and retained its flat tappet cam. The engine was discontinued in 1996 when engines were required to convert to OBD2. The 302 and 351 share the same 4 inch bore diameter. The

351 has a taller deck height to fit the longer crank. This

means it is a tighter fit into a Series Land Rover engine bay.

There is enough space to switch spark plugs in

a 302 installed in a Series Land Rover engine bay with Series

inner wing panels. Working at the sides of the engine is tight

but doable. If

you install a 351 I strongly suggest converting to Defender inner

wing panels in order to gain additional clearance. This

isn't necessary but it would make working on the engine easier.

The left side rear spark plug might be really hard to change. Conversion

to power steering to get the stock steering box out of the way

is a necessity.

When swapping to a V8, most people overbuild engines

beyond what would work well with their Land Rover, then either

have no low end power or break a lot of drive train parts. A

bone stock Ford 302 with low compression heads and 500 cfm carburetor

has more power at idle than a healthy 2.25L petrol Land

Rover engine with 8:1 head does at peak. Bone stock the

302 will let your Land Rover climb paved roads in the mountains

at the speed limit and accelerate onto a freeway at very acceptable

rates. A 302 is a good choice for driving without a trailer

and for driving with small trailers in the hills.

If you plan to spend time towing large heavy trailers

in the mountains and feel a need for more power there are two

immediate choices: a 302 with stroker crank or a 351. A stroker

crank adds its power at the low end RPM, from idle to around

4000 RPM. A

stroker crank by itself brings the engine displacement up to 327

cu in. A complete stroker kit with crank, pistons & rods bring

the 302's displacement up to 347 cu in. All without reducing

engine efficiency or increasing the physical size of the engine. However,

a 302 with stroker kit is more expensive than a bone stock 351.

A 351 is basically a 302 with longer crank and

additional block height for the additional piston movement. It is a

good base engine if your plans include towing an airstream to a

base camp in the mountains. If you want to tow a really big

airstream a 351 engine with a stroker kit displaces 392 cu

in. Big block displacement in a small block form factor.

I suggest realistically evaluating your needs then

choosing the base engine and displacement that best fits your

needs, realizing that a bone stock 302 is more then enough engine

for any Series Land Rover not towing heavy loads through the

mountains or at really high altitudes. My suggested rule of thumb

would be a 302 for light weight towing or no towing and a 351

base engine if you plan on towing medium or heavier trailers. The

longer the crank, the more bottom end torque and the more apt

you are to break drive line components as well as make those

steep climbs or tow a heavier load. The smaller the V8

the easier it is to get better fuel economy. I have found

that my 5600lb Land Rover powered by a 302 set up for economy

can climb anything my tyres can find traction on and can go the

speed limit on mountain roads. I

no longer spend my mountain driving hours figuring the best

down shift strategies for tackling the mountain. I just

sit back and enjoy the scenery as I pass the slow vehicles on

the hill.

Here's a quote from an article I once read: " Part

of building an engine is knowing exactly what you

can afford, then not giving in to ego and the temptation. And that’s the

mistake a lot of us

make along the way. We want to impress our peers. But these are the wrong reasons

to build

an engine. Don’t build an engine to impress anyone beside yourself, because

you alone will

have to live with the result." This is worth committing to memory and

repeating whenever looking through a catalogue of speed parts and accessories.

What year engine should I choose?

There were a lot of bad things done to these engines

in the name of emissions compliance. It wasn't until the

late 1980's when computer control got good enough to provide

cleaner engines with increased engine power and fuel efficiency

that the engine became any good again. If you are uncomfortable

with fuel injection and weary of engine computers my advice is

that you pick an early base engine built before air injection

was added. 1968

through 1973 base engines do not need to pass any periodic

emissions testing in any State (as of 2008) so you can build

it any way that you wish. As a minimum I advocate having a closed

positive ventilation crank case system with a PCV valve (positive

crankcase ventilation valve), that you use a 180 degree thermostat

and that you build and tune your engine for best fuel efficiency

The closed crankcase system not only reduces emissions it keeps

the inside of the engine cleaner allowing you to drive more miles

between engine rebuilds. A warmer running engine reduces engine

wear and pollutes less. All

good things in my book.

If

you are comfortable with EFI or willing to learn how it works,

I suggest 1987 or newer engine, with the MAF equipped 1989

through 1993 Mustang 5.0 as being the best of the newer

engines, and newer distributor less engines being a bad idea.

1989 through 1993 Mustang 5.0 engines, have more power then the

earlier factory versions, are more reliable than

the other heavily SMOG equipped engines, have a barometer that

allows the engine to tune itself for optimal driving at different

altitudes and a computer that self adapts for different engine

configurations, such as headers or non stock cylinder head.

It is generally a bad idea to use one of the newer

distributor less engines in a vehicle that occasionally is expected

to do deep wading. Distributor less

engines have a crank angle sensor down at crank level. This

is an essential sensor that will keep an engine from running if

it breaks. This crank angle sensor usually sits just above the

oil pan and tends to break when immersed in cold water. If

you have one of these engines in a vehicle used off road it is

a good idea to try to protect the sensor and to carry multiple

spares.

In some states the newer engine means

the a pre-SMOG vehicle is required to undergo periodic emissions

testing and pass at the levels in effect for the year the engine

was manufactured. This

could mean all new fuel tanks, charcoal filters and a catalytic

converter. A

way around that if you live in a state that requires emissions

testing on old vehicles with early 1990's engines is to have

a base engine from a year that does not require periodic emission

testing and convert that engine to EFI. This

gives you the power and economy of a more modern engine along

with an engine that emits lower emission levels than when your

Land Rover was new and when your base engine was new. I'm

all for lowering engine emissions but there are practical limitations

when upgrading 40 and 50 year old 4X4's.

Carburation of fuel injection?

Carburetors are comparatively simple, and relatively easy to troubleshoot They have an idle circuit, a main circuit and an accelerator circuit which you set up to give you the best characteristics for your home conditions. They can not compensate for altitude or temperature and rely upon a choke for cold starts. They cannot self adjust for engine temperature, air temperature or altitude changes. Their only advantage is their simplicity. EFI is designed to continually monitor engine and operational environmental conditions and constantly adjust your fuel delivery and engine timing to provide maximum power at any altitude and outside temperature while minimizing emissions. Better power at any altitude, better engine starts, better fuel economy, all while burning cleaner that a carbureted engine. The drawbacks are that you need to learn the basics of EFI and you need to add a fuel return line back to your fuel tank. EFI can be added to any of the pre-1996 302/5.0 engines.

- The best EFI for the 302 is considered to be the Mustang 1993 system.

- For a conversion, obtain a used upper and lower intake manifold and distributer from a wrecking yard (distributor for a core when purchasing a rebuild). Look for a computer, usually inside the passenger side kick panel. Computers are different for different 302 EFI systems, so be sure to get one off a Mustang with HO EFI. The computers are different for Mustangs with automatic and manual gearboxes. If you are buying a rebuilt one, say you have a 1993 Mustang GT with 5.0 and five speed gearbox. The type you are looking for is a A9L (used 1989-1993). Everything else should be new Otherwise it is too easy to get the wrong part (many look alike) or one that is worn and out of spec..

- For an EFI wiring harness look for one designed for use on kit Cobras. They come with everything you need including fuses and relays. The only problem is the wiring going to the computer will be too long. You can always just loop the extra up.

- There is an EGR spacer that goes between the throttle body and the intake manifold. If you are not building the engine to meet factory emissions requirements you can eliminate it and replace it with a special plate that holds the accelerator cable in place.

- You will need to modify the accelerator pedal to hold an end of the throttle cable. I used a pedal off a 200 tdi Defender. If you are handy with welding you can cobble something that works.

- Use a standard 1993 Mustang ignition coil. Whenever sourcing parts, just tell the drone behind the counter you have a 1993 Mustang GT with 5.0 & five speed manual gearbox.

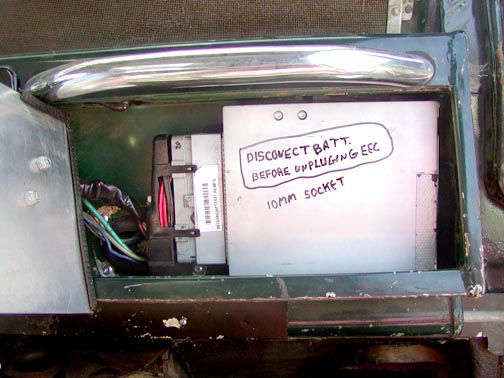

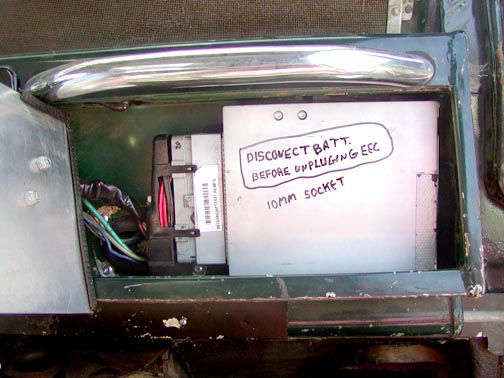

EFI computers do not like to get hot or wet. A Series

Land Rover has the perfect place to mount one. The right side

instrument shelf area.

Ford EFI computer mounted on its side with rubber padding on top,

bottom, side, front & back

There is a hole already at the correct location. The

factory bulkhead hole for a RHD steering column. I just removed

the cover and enlarged the hole a little to fit the Mustang bulkhead

gasket. Then I added a sheet metal plate in front of the

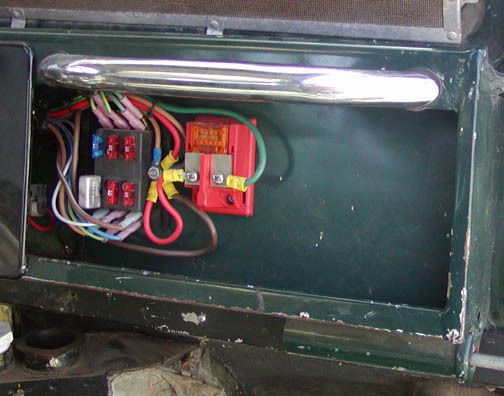

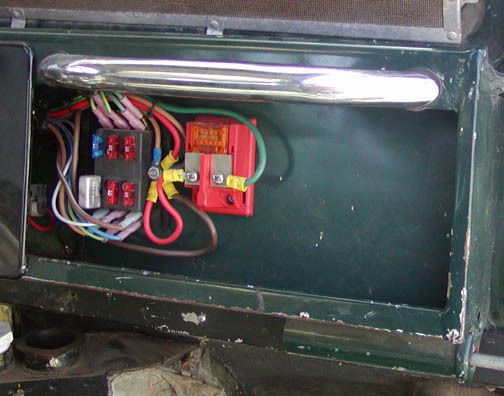

EEC. The EFI main power relay sits inside beside

the computer. The panel make a good place to mount fuses.

Main fuse panel mounted to cover in front

of the EEC. The big

60 AMP fuse is for the 4 roof lamps

200 tdi pedal. I had to grind off the bottom stop on the pedal arm

|

Where the accelerator cable went through the bulkhead I use nylon spacers to take up the

free play between the cable housing end and the pedal connection

|

Your engine on Speed equipment

A pure stock engine will work just fine and

be a major power upgrade that can deliver the same or better fuel

mileage as the Land Rover 2.25L engine. However there is a

lot of highly visible speed equipment out there. One

look through the Summit Racing Catalogue can get you dreaming about

all kind of exotic parts that will produce a zillion horse power

and be the envy of everyone who sees it. BUT a lot of these goodies

will make your Series Land Rover less flexible to drive, less reliable,

and almost impossible to drive past a gas station. Much of this

stuff is designed to dump more fuel into the engine and to provide

more power at high RPMs by stealing it away from the low end. Many

things that work well at high rev's such as long duration cams,

big valves and big intake passages just hinder power at the RPMs

most off road trail rigs live at. In most cases you can get more

low end power out a a bone stock 302 or 351 at normal off road

RPMs than you can out of a very expensive racing crate engine. Whenever

you want to evaluate a product, ask to see the power curve between

idle and 3000 RPM. Many manufacturer's curves start

at 3000 RPM and go up from there. There is usually a reason

for that. Forged pistons, crank and special lightened rods

are designed for engines that produce in excess of 500HP and rev

past 7000 RPM. They are both expensive and total overkill

in engines set up for trail drives and normal highway use.

That said, there are special parts such as high lift

shorter duration cams designed primarily for towing, aluminum

heads designed to flow well at low RPMs and headers that can improve

the low end power of your engine should you decide that you just

NEED more. And a good solid spark never hurts.

CAMs

First some Ford small block basics: Flat tappet

302 & 351

cam shafts are interchangeable but they have a different firing order.

The Firing order for flat tappet 302's and non HO versions of

the roller tappet 5L engines is 1-5-4-2-6-3-7-8. The

351 and later HO 5L roller tappet engines shared a firing order:

1-3-7-2-6-5-4-8. This tidbit of information is of interest if you

are converting an early flat tappet engine over to early 1990's

Mustang 5.0 HO SEQUENTIAL EFI. If you replace

the early flat tappet 302 cam with a 351 cam and move the spark

plug wires around you will have a sequential EFI system

that injects fuel into the cylinder at just the right time for

the spark. The

stock 302 flat tappet cam with work with Mustang 5.0 HO EFI system but the idle will not

be quite as smooth, the power output less, and the fuel economy might not be quite as

good as it could be.

A good flat tappet cam to use in a 351 or an early

302 that has been fitted with Mustang sequential EFI is a COMP

# 35-255-5, grind # FW XE254H-14 Here

is a description of this CAM's performance provided by a COMP customer

engineer: "Basically,

it is going to improve performance all across the power band. It

is not that much larger than the stock camshaft, but has a more

aggressive lobe profile (which makes the valves open and close

faster, therefore increasing low to midrange torque), and has a

bit tighter lobe separation (which will tighten up the power band

a bit, therefore making it more responsive). With the more

duration it will make the application turn more rpm, and more upper rpm horsepower.

Effectively making the engine perform better all across the board. Where

your stock camshaft will work somewhere between off idle to 4500 or so

Many 1985 and newer 302 engines with roller cams retain the old timing, including 302 engines built for Broncos and trucks. If you do not the the vehicle an engine came out of you really have no way of knowing which cam it has. If buying a rebuilt engine specify a HO cam. I suggest a COMP 35-512-8 cam for a roller cam engine using 1993 Mustang EFI. This is their best cam for low end torque and provides good fuel economy. The power curve is 1200 RPM through 5200 RPMIt is their best cam for towing (low end torque) and fuel economy and your best bet for off pavement driving.

Cylinder Heads

A stock Ford 302 with cast iron cylinder heads is just

slightly heavier than a stock Land Rover 2.25L petrol engine. Replace

the 302's cylinder heads with aluminum heads and you have an

engine that is almost 50 pounds lighter in weight than the Land

Rover four.

There are a number of compression

ratio stock heads available from Ford plus several aftermarket

performance heads. As a rule the stock Ford heads

are not known for high rates of flow. The best of the factory cast

iron head is the is the GT-40 E7TZ (casting ID F3ZE-AA). That's about 30 cfm better than

the standard 302 head. They

have an aluminum version that flows about as well as the Edelbroch performer

head. The aluminum "street" heads flow on the average of

about 60 cfm greater than the stock 302 head (30 cfm better than the iron

GT-40 head). If you find yourself looking at the aftermarket heads,

don't forget that larger port passages and valves actually hurt flow and

power at the low RPM range where 4X4s live. High flow at 40 or 50%

of cam lift with the smallest valves and port passages are your best bet

for off road use.

Most of that advertised performance boost from aftermarket special

performance cylinder heads come

in at higher than 4000 RPM, and flow less than a stock Ford cylinder head below about 3000 RPM. As an example:

The complete Edelbroch performer series package, cam,

aluminum heads, carb, intake manifold and headers (What about

$3500?) gets you an increase of only 20 lb/ft of torque over

a stock 302 at 3000 RPM. The real gain is above that RPM Their advertised curve does not go below 3000 RPM where they can perform worse than a stock head and cam.

Aluminum heads cost in the $1200 to $1350 price

range per pair. I looked at air flow specs of about 10

different aluminum "street"heads. Of

the bunch the one that looks the best at low RPMs is the

Air Flow Research 165 head, cat # 1400. On

a stock engine they dyno'ed to 302 lb/ft torque, 119 HP at 2000

RPM and 311 lb/ft torque and 177 hp at 3000 RPM. That's

roughly about 1/3rd more torque than a stock 3.9L Land Rover

V8 puts out at those RPMs. When

in doubt ask the manufacturer how the head affects power curves

in the 2-3000 RPM range.

As a rule of thumb, figure about 3 percent extra power for each

higher compression point. Also higher compression helps long

duration cams work better. It is up to you to decide if that

3 to 6 percent extra power is worth the price of premium gas

every time you hit the pumps. I

went with the low compression 9:1 heads that allowed me to run

regular gas. And if you

are shopping for cams make sure the manufacturer knows your engine

will live below 3000 RPM and that is where the power needs to

be.

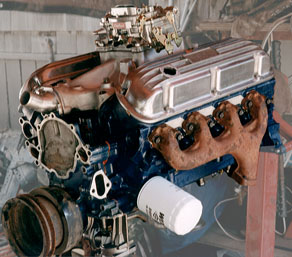

Exhaust Manifolds or Manifold Destiny (required for swap)

Ford exhaust

manifolds almost all exit the rear of the engine. Series Land

Rovers have a vertical bulkhead with makes this style incompatible.

To the best of my knowledge there are only two stock cast iron

manifolds that can work in a Series Land Rover. One is a pickup

left side exhaust manifold. The other is the early Falcon V8

left side exhaust manifold. Ford exhaust manifolds can be mounted

on ether side. So you will need two left side exhaust manifolds.

Of the two types the early Falcon one will fit better. You can use other stock cast iron Ford exhaust manifolds of you mount them backwards so that the exhaust exits at the front of the engine. This is a bad idea on the left side because it obstructs removal of the oil filter. It is a good idea on the right side because you can move the hot down pipe away from the front propshaft and starter motor. A

block hugging header can be made to fit but generates a LOT more heat inside your tiny poorly ventilated engine bay. Vapor lock easily becomes a major issue with steel headers.

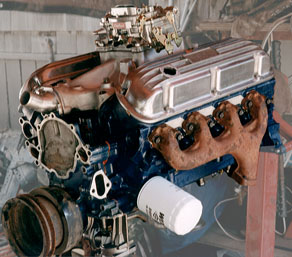

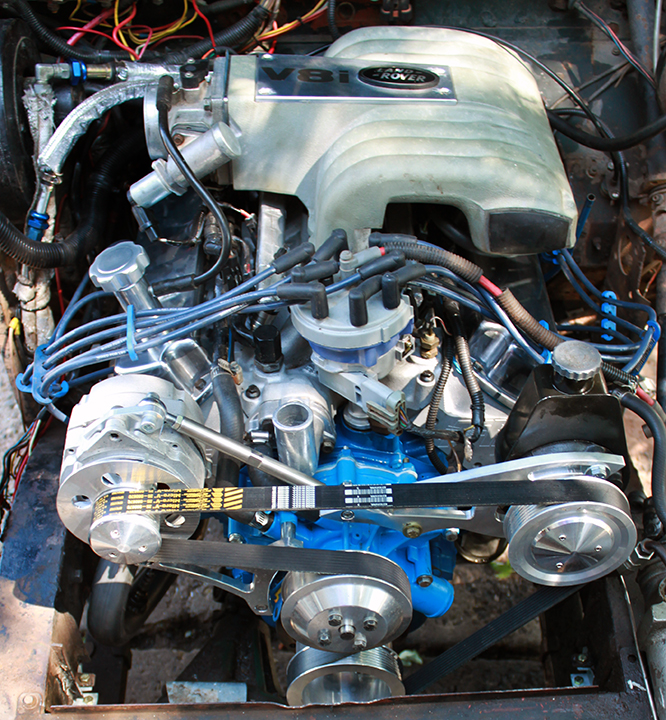

This is my engine being built,You can clearly see one of the

early Falcon V8 exhaust manifold. This manifold easily clears the fuel filter area, most engine mounts and allows you to easily route the down pipe away from a left side mounted clutch cylinder & hose. I used a left side Mustang cast iron exhaust manifold on the engine's right side. This manifold is mounted on the reverse side puts the down tube at the front of the engine, allowing for a gentle bend and plenty of clearance for the engine mount, front propshaft and the starter motor. Whatever exhaust manifolds you use, it is important to mount them to the engine BEFORE fabricating the frame mounts. That way you can assure freedom from interference.

Also note the

oil filter aims directly at the frame side rail. The Ford

filter (shown) is too long to fit and be removable. A right angle

adapter from Ford Racing is the best solution. A Dodge

318 V8 oil filter is shorter than the Ford filter and can be used on the Ford engine.

There are a number of block hugger shorty headers that point

down instead of to the rear. One problem is that there are a large

number of engine mounts used with the Ford small block engines

and some interfere with different headers. Steel headers throw off a lot more heat than cast iron exhaust manifolds and the Series Land Rover engine bay is a very small box enclosed on 5 sides. Vapor lock can easily become a major reliability issue when you use headers. I have used both cast iron exhaust manifolds and headers in my truck. I did not notice any power or fuel efficiency differences. The advantage to headers is usually seen at high RPMs where my truck very seldom ventures. I found vapor lock plagued me with unwrapped steel headers. Header wrap drastically reduces the duty life of headers. My wrapped headers lasted about 2 years before disintegrating to rust flakes.

Ford SOV has a shorty exhaust header that will work. "Street

Rod Headers" #M-9430-S302. These require you to use engine mounts

270-2221LH and 270-2220RH.

Ford SOV block hugger headers

Headers currently available are designed to fit the newer heads

with the small diameter spark plugs. If you use the headers

with early heads that take the large diameter spark plugs, check

the spark plug to header clearance. You may have to do

a little grinding on the header mounting surface to get enough

clearance to replace the spark plugs. Also, you might

or might not get a good seal with a stock exhaust manifold gasket. Best

bet is to spring for the thicker higher quality header gaskets. They

do a much better job of sealing. This is very important

if you are using EFI as the O2 sensor would get incorrect readings

with gasket leaks.

Motor Mounts

You will need to fabricate new frame mounts and there are a

large number of Ford small block engine mounts to choose from. I

decided to use a mount designed for Baja racing Broncos and sold

by Wild

Horses Four Wheel Drive. Of course this was

after my 302's fan went into the radiator during an off road

trip.

|

Extreme Motor Mounts. These will help keep your motor and

fan blade out of your radiator in extreme off-road situations.

The extreme motor mounts were designed to withstand the riggers

of Baja racing. They come complete with urethane bushings,

unpainted.

Wild Horses item # 8036 |

Oil Filters (required for swap)

The oil filter sits near the bottom of the

engine and points out horizontally.

Unfortunately this is at frame level and there is insufficient clearance

to remove the stock Ford oil filter. There are

a few ways to get around this problem.

One is to use a Dodge 318 V8 oil filter. This filter

uses the same mounts and sealing surfaces as Ford but is considerably

shorter.

Ford Racing has an oil filter adapter for the hot

rod set. It is basically a right angle adapter similar in shape

to the oil filter adapter used on the Land Rover four cylinder

engine. This turns the spin on oil filter 90 degrees. The Ford

part number is M-6880-A50. There may be a slight interference at the oil pan flange. If there is grind off a little of the flange edge.

Ford Racing right angle filter adapter

Or if you have space you can go with a remote oil filter adapter

on the front left inner wing. I have a windscreen washer bottle

and a radiator recovery bottle in that location so no space for

a remote oil filter.

Accessory Brackets

Ford tends to mount both the alternator and power

steering pump down low where it will interfere with the

Series Land Rover frame and are likely to be submerged during

deep wading. I

recommend mounting the alternator at the top of the engine. Adding

accessories such as a power steering pump or air conditioning

is usually a matter of finding the right bracket and modifying

it if needed. There are a large number of accessory mounting

brackets available to choose from if you use stock accessories

in one of the stock locations. Most

small blocks go into engine bays that are a lot wider than a

Series Land Rover bay and the accessories may not be tucked in

close. Chances

are you will need to adapt or fabricate mounts for accessories.

For pre-1985 engines with flat tappet cams:

|

This is my Delco alternator and mount. The top bracket

is an aftermarket GM V8 alternator top bracket. The bottom

bracket was fabricated from scratch. |

|

This is an early Ford 302 power steering pump bracket that

has been modified to fit the GM "canned ham" style power steering

pump |

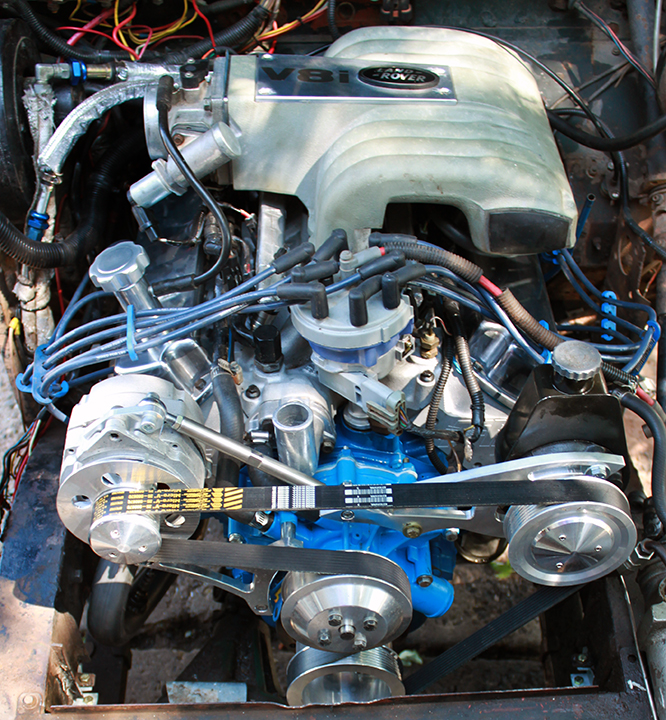

For post 1995 engines with a roller cam you need to use a serpentine belt (An early cam gear cover might fit onto a later engine allowing you to keep fan belts but I have not verified it). There are several companies making brackets for engines using serpentine belts.

|

I used conversion kits made by CVF Racing. Their Ford 5.0L & 5.8L serpentine conversion kit. The spacing on the engine mounting allowed me to relocate the brackets higher on the engine. I needed to order some different length spacers and the company was very helpful. |

Balance factor: - harmonic dampeners

There were many versions of Ford small blocks manufactured

over 3 decades of production Some things can be mixed but

some parts can not. You need to have the right harmonic

dampener flywheel and bell-housing the the version of engine you

are using.

1868 - 1980 302 engines were built with a 28 ounce imbalance

factor

1981 - 2001 302 engines were built with a 50 once

imbalance factor

1969 - 1997 351 W & C engines were built with

a 28 once imbalance factor

Severe engine damage will result if you use the wrong flywheel

or harmonic damper on your engine.

Flywheels and Starters

Ford used two flywheels, 157 tooth and 164 tooth. You need to

match the flywheel with the starter motor and the bell-housing

The starter motor is on the same side as the front prop shaft. I

recommend using a geared starter motor. They are smaller

than the stock type starter motor and will provide more clearance

for both headers and the front prop shaft.

Engine Cranks

If your engine is below 500 hp and stays below 7000 RPM, the

stock crank shaft , rods and pistons work just fine and are way

cheaper than the forged, lightened custom stuff. A stock 302 will

provide move torque than the Land Rover aluminum V8s. It

provides plenty for most all off road driving conditions and for

light towing. However sometimes you need more low end torque for

towing heavier trailers into the mountains or just because you

want to impress you buddies with how much of your expensive tyre tread

you can leave behind climbing a steep rock slope. The easiest

way to increase low end torque is to use a longer crank shaft. A

stroker kit consists of a crank, rods and shorter pistons. It

is cheaper to install a 351 engine but the 351 takes up a bit

more space in the small Series Land Rover engine bay.

A 302 with a 3.4 inch stroker crank kit with pistons can displace up to 357

cubic inches. The

extra length of the crank throw adds about 70-80 lb-ft torque

and lowers peak torque by about 300 RPM from the same engine with

a stock crank. (The stock 1970 Bronco engine would get about 320

lb ft peak torque at 2300 RPM) The stroker crank increases displacement

to 342 cubic inches using standard diameter pistons. 30

over pistons raises displacement to 347 cubic inches. All with

no increase of external engine dimensions! This combination

can provide you with axle breaking power at the low end, but

swapping in a 351 is cheaper and a 351 can be stroked to 392 cubic

inches giving you big block performance in a small block form

factor.

There are a lot of products and manufacturers out there. I

suggest doing a web search and compare products if you decide

to use a stroker crank.

Oil Pans (required for swap)

Early 302 pans have the deep sump at the front which will interfere with the differential on full downward articulation. Look for a center sump oil pan and pickup from a 1985 and newer 5.0. Be sure to get the dip stick and dipstick tube as well.

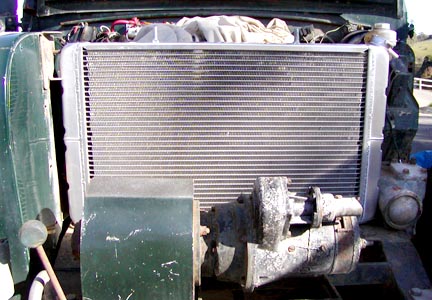

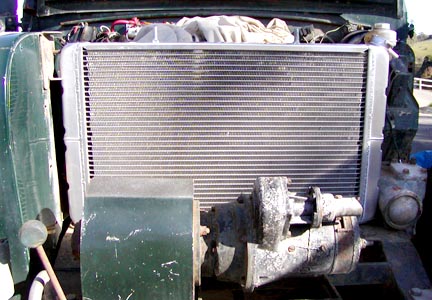

Dealing with the engine length

The small block Ford engine is longer than it's Chevy equivalent

because of the space needed for the front mounted distributor.

A Series Land Rover 4 cylinder engine bay does not have enough

space for the average 302 with mechanical fan and a vertical

flow radiator mounted behind the front cross member. The easiest way to provide space is to mount an aluminum cross flow radiator on top of the front cross member and use electric fans. You want to use dual puller fans mounted on a shroud behind the radiator for maximum cooling. Dual fans will put a fan on wither side of the water pump pulley. I choose a radiator that provides space on the right side for the prop rod and on the left side for the power steering box. My choice was Griffen Thermal Products 1-59241-XS which has an overall width of 27.5", height 15.5". Have the company mount the shroud and fans. If you misalign drilling the holes you will puncture the radiator and void the warranty. This radiator with the 2 shrouded puller fans have worked very well for me keeping the engine at operating temperature driving through summer Arizona and Utah trails. When I installed the new engine with the serpentine belt I needed slightly more space. I hammered the back of the headlamp buckets in a little and got what I needed. of course it would not be an issue with a newer truck that had headlamps in the wings.

.

My Griffen cross flow radiator sits on top of the front cross member is the same height as the radiator bulkhead, sits against the power steering box on the vehicle left side and has enough space on the other side for the bonnet prop rod and for wires to pass

If you need additional engine bay length, a method is to cut the radiator cross member off,

move it forward one inch then re-weld it. . You will need to heat up the

top steering relay lever and bend it rearwards one inch for the

stock steering to work. It does not affect a power steering conversion.

When you move the cross member forward an inch you cut the radiator

bulkhead mounting tabs off one inch and drill new mounting holes

1 inch to the rear. The end result is you have an inch more space

and everything looks totally stock.

Ignition

Here is where the Ford small block conversion really shines.

The distributor is in the front and very easily accessible.

The GM distributor is in the rear tucked up against the bulkhead.

This means you have to remove any bonnet mounted spare and lift

the bonnet to vertical to begin to get access to the GM distributor. Ford offers a rubber boot that covers the top of the distributor

providing splash protection. There are in the $15-$20 cost

range.

Ford offered a Duraspark II system during the seventies that

provides a breakerless very high voltage ignition system for engines using a carburetor.

It provides good spark and you don't have to worry about point

slippage or wear. Engine bay heat usually kills them over time. I mounted the electronic box on the inside

of the right inner wing at the very front. It was the coolest

out of the way spot I could find and is close to the distributor. You want to mount the control box in the coolest part of the engine bay. If using EFI, the stock parts work well.

The Duraspark II unit and the EFI ignition system need a starter circuit sense wire for cool

weather starting and there is no place in a stock LR positive

earth wiring harness to connect this line to. The sense line bypasses

the resistor wire for higher voltage to the ignition during start

and it retards the ignition slightly for easier starting.

I ended up getting a late seventies Ford starter relay and wiring

it in next to the stock positive earth starter button. The Ford

relay has special connection for the electronic box sense wire.

I wired the Ford relay activation wire to the stock positive earth

manual starter switch so that the stock starter switch activates

the Ford relay. So I start the engine the same way I always have.

|

302 flat tappet distributors

used an iron drive gear. 302

roller cam distributors used a steel drive gear. If you are converting

a early 302 engine with flat tappets to EFI you will need

to fit the EFI distributor with an iron drive gear. |

Positive earth LR starter switch warning

The Ford starter motor draws a lot more current than the LR starter motor. If you try to wire the stock push button starter switch directly to the starter motor the current will weld the contacts closed so the starter motor will continuously turn. You need to use a starter relay to handle the current. I wired my stock push button starter switch to my relay which provides power to the starter motor.

Return to page top

|