|

About The Green Rover

My 1960 through 2002 Land Rover Dormobile

owned since March 1978

3/4 view taken in 2016 soon after my new 2002 rear door was mounted.

I washed and waxed the truck to try and match the fresh paint on the new door.

If you are wondering, the colour is British racing Green.

An Introduction:

When I purchased my Land Rover in 1978 she was broken down and had been left to sit for a couple of years. The owner had inherited the truck from an uncle in New Hampshire, dove her to the west coast, then up and down the west coast to participate in craft shows. He only knew to put oil in the engine. He drove her until the rear differential ran dry, put the transfercase into 4WD then drove it on the front wheels until the transfercase went dry. She was then towed the short distance home and just sat until I found her a couple years later.

This was during the time when Land Rover had recently left British Leyland to once again become an independent company. Land Rover was just starting to set up a parts dealer network and new replacement parts were scarce to nonexistent in the United States. Thankfully I met Jim 'Scotty' Hewet who not only mentored me on Land Rover mechanics but also had a large stock of used Land Rover parts. My truck was missing a number of parts and what was left were mostly completely worn out. During those early years there was no thought of using exact year and model specific parts, it was more a mater of finding any serviceable used part that would fit and work. So from the start she became a mixture of SII and SIIA parts. A couple years after I got the truck running again, Scotty informed me that the truck had been in a front end accident early on and that it looked like the front clip and front quarter of the frame replaced. He showed me the weld marks where the frame sections were welded together. I never had a correct truck to restore to original and the truck had several parts from trucks throughout the sixties before correct period parts became once again readily available. So I never concerned myself with originality. Though my truck has been well cared for over the decades she has had a hard life traveling long distances over several difficult trails. Over time, by upgrading broken parts, the truck has become a lot stronger then when she left the factory and parts have been added to make long duration travel into primitive locations more comfortable.

Oh, about the name "The Green Rover". At the time I had a red 88 and I used the vehicle colour to let people know which truck I was referring to. The name just stuck. If you would like to read more about my first days with my truck you can purchase my second book, "A Girl and her Land Rover, an Auto-biography".

My Goal:

I enjoy traveling alone into scenic locations to immerse myself in the peace and beauty of nature. So my goal is having a dependable truck that could take me into primitive locations and allow me to camp comfortably for weeks at a time, only coming in about once a week for fuel and groceries. The last thing I wanted was to find myself broken down, alone, and miles from any help.

My Strategy:

Since I'm not concerned about originality, my strategy is simple:

If a part wears out, replace it with the highest quality replacement part I can find

If a part breaks, replace it with something stronger

I want to keep my Land Rover as much Land Rover as would fit my strategy, preferring genuine and OEM parts to aftermarket parts or parts from other marques when a Land Rover part would fit my needs. Land Rover made improvements in the trucks as the years went by so I upgraded to newer Land Rover replacement parts where there were major improvements to be had. For instance, my truck has heated windscreens (introduced in 1967), a dual speed wiper system, Defender door seals, and Defender seats.

Inherent weaknesses of Series Land Rovers:

-

109 front brakes: Both front brake shoes on the heavier 109 are forward facing. What this means is that all four front brake shoes apply pressure on the drum in the forward direction to maximize the ability to stop in the forward direction. This shoe arrangement applies minimal braking in the rearwards direction, relying on the smaller rear brakes to do the primary braking when the vehicle is moving in the rearward direction. What this means is that it is very difficult to apply enough brake pressure to keep the vehicle stationary when stopped facing up hill. I consider a front disc brake conversion with power brakes to be an important safety upgrade for the 109.

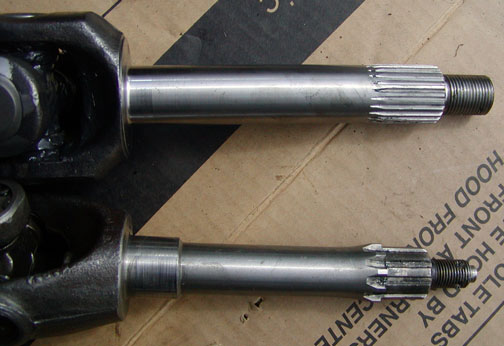

- 10 spline axles: The 10 spline axles on an 88 and SII/SIIA 109s are the weakest part of a stock Series Land Rover drivetrain. The heavier 109 breaks them more often. I broke 7 rear axles before I upgraded to the SIII 109 Salisbury axle assembly. The Salisbury is a Dana 60 built under license and has stronger 24 spline axles. Using the SIII rear propshaft, the SIII Salisbury is a direct bolt on upgrade for a 109. 88s can be upgraded with 24 spline axles and a 24 spline differential. For people doing extreme rock crawling there are even stronger 32 spline hardened axles available, but that is an expensive extreme overkill for 99% of trails.

24 spline axle top, 10 spline axle bottom.

- Series gearbox: The Series Land Rovers use a gearbox that was designed in the early 1930s for lighter weight automobiles. Though the box has been upgraded over the years it is still a weak design for a heavy off road vehicle. The gearbox proper is the second most weak assembly. The transfercase was designed specifically for the Land Rover and is quite robust, able to hold up behind most American V8 or 6 cyl engines. Advance Adapters make adapters that connect a Series transfercase to common American gearboxes.

Land Rover gearbox left, NP435 gearbox right

- Series differentials and ring and pinion gears: These parts are strong enough to hold up under moderately difficult trails. Most owners never have problems with them. However if you intend to do more extreme travel or want extra insurance against drivetrain breakage in remote locations you should consider upgrading these assemblies. Locking and limited slip differentials are stronger than stock Series differentials while also increasing the truck's off road abilities. GBR Utah is the go to place for stronger ring and pinion gears that handle extreme off road forces and higher horsepower engines.

My Land Rover's drivetrain:

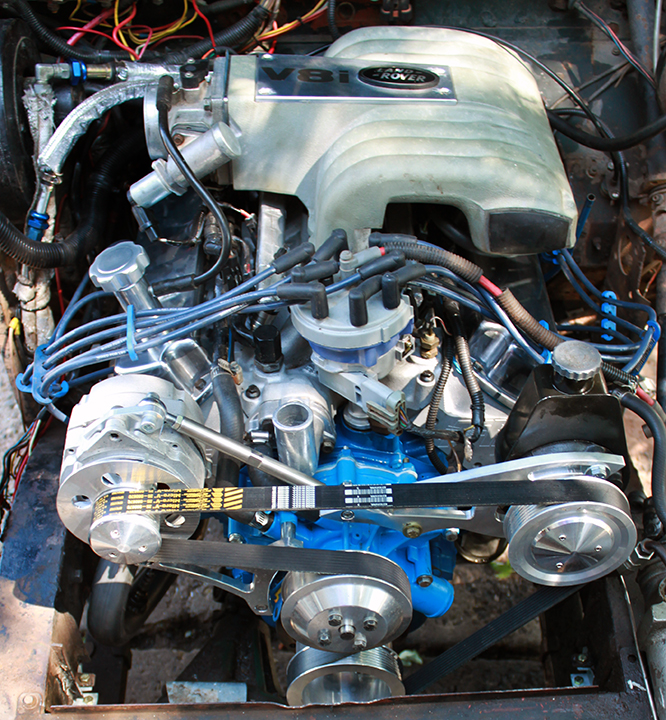

- Engine - Ford 5.0 with 1993 Mustang fuel injection. The tall Ford truck EFI is an iffy fit under the bonnet

- gearbox - NP435 with close ratio gearset

The MP435 is a top loader gearbox with massive gears

- Transfercase - Ashcroft high ratio Series transfercase

- Emergency Brake - I replaced the stock mechanical drum brake assembly with an X-Brake, which is a mechanically operated disc brake. The disc brake does a much better job and is not effected by any oil leaking out the rear main transfercase seal.

- Rear axle assembly - Salisbury with ARB air locker differential, Maxidrive rear axles and drive flanges

- Land Rover front axle assembly - TruTrac front differential with GBR Utah ring and pinion gears, and SeriesTrek 24 spline axles.

Left: TruTrac 24 spline diff

with beefy GBR Utah ring gear. Right: 10 spline Quaif limited slip with stock

Series ring gear. Note the line in the ring gear. There is a spacer plate behind the Series ring gear to fit the Quaif.

Bottom is the oversize U joint assy. of the SeriesTrek 24 spline axle.

24 spline outer front axle top, 10 spline outer front axle bottom. I broke two 10 spline front axles before

converting to the 24 spline front axle.

- Wheels and tyres - The wheels are the 7 inch bead to bead steel wheels that came standard on European Discovery I and as an option on the Defender. These are the widest steel Land Rover factory wheels that fit Series and Defenders, and are stronger than the Series specific wheels. These wheels allow a wider selection of tyres to choose from. The tyres are 33.3 inch dia (stock for a 109 is 32 inch dia) BF Goodrich mud terrains, 255/85R16. As of 2019 they are KM3. I have been using this size mud terrain tyre since 2004 and get a little over 50,000 miles on them.

The drive train overall low range first gear ratio is 50:1 at the axle. Stock Series is 40:1. With 33 inch tyres, 65 MPH is achieved at 2650 RPM.

Suspension:

I've kept the suspension system basically stock. Mainly because I do not like the performance characteristics of parabolic springs, nor the quality of aftermarket springs. The springs are genuine Land Rover one ton springs, which in reality is a bit stiffer than I would prefer at the rear. To minimize the friction between the individual leaves, I used UHMW (ultra-high molecular weight) Polyethylene plastic sheets between each leaf, thus virtually eliminating leaf to leaf friction.

This plastic provides a low friction surface, similar to Teflon tape, but with a much higher abrasion and puncture resistance. It was designed specifically for commercial use on chutes, packaging lines, slides, and anywhere high pressure metal to metal sliding contact occurs. It also provides sound dampening, eliminating squeaks and rattles caused by adjacent parts movement. The plastic's temperature range is -40 to +225 degrees F. Reducing the leaf to leaf friction provides a ride closer to having parabolics without the parabolic springs tendency for side sway and axle wrap. I installed the plastic strips in 1995 and they are still functioning today.

I replaced the stock bound rubber spring and suspension bushings with unbound greasable polybushings. Heat caused by friction causes poly bushings to die early and dry bushings causes squeaks. Greasable bushings from GBR Utah solves those problems allowing for freer spring movement.

A hole is drilled into the spring bolt and the grease is injected through holes into the bushing insides.

Even with the hole I have yet to break one of these bolts.

Shocks are OME, and extended military shackles have been added for a one inch lift (civilian front spring mounts). A three degree wedge was added at the front axle perches to correct the king pin angle.

Stock front shocks severely limits downward spring travel which is why you commonly see a Series truck lifting a front wheel on a trail. Downward articulation can greatly benefit from longer shocks and a higher top shock mount. I've just never had the money ahead to have the modification done.

On board capacities:

Fuel - 46 gallons

Drinking water - 15 gallons

Propane - 5 gallons

Air tank - 2.5 cuft ( I have a on board 12V air compressor with a air tank)

Learn more about my truck:

Pictures and descriptions of features

Front view

Left view

Right view

Rear view

Return to page top

|