|

Demystifying the Series Land Rover Transfercase

The purpose of this page is to provide basic information about identifying transfercase gears and gear ratios then to show what is inside a Series transfercase and explain how it works. For assembly instructions please refer to the factory workshop manual. I recommend against the Haynes manual for this operation. You should be aware that pre-metric Series Land Rovers use Whitworth fixings (coarse thread) where they screw into cast parts and British Standard Fine (BSF) for fine thread applications. BSF is very similar to American fine thread standard but the thread pitch is different. Mixing the two will produce a weaker hold and damage threads. Whitworth fittings are used on both axle assemblies, the gearbox and transfercase. The transfercase uses1/4W and 5/16W for most nuts and studs used on a transfercase. The cover over the shift fork uses a 1/4W and the nuts holding on the transfercase mounting plates are 3/8W. You can probably get away with having just these sizes for working on your Land Rover.

The common Series transfercase found in Series II and newer 88 and 109 Land Rovers comes with two sets of gear ratios, the early ratios found in suffix A & B transfercases and the ratios found in the suffix C and newer boxes. The high range is the same on both the early and later transfercases but the low range gears in the early transfercase are slightly lower. The later transfercases were strengthened by increasing the diameter of the intermediate gear shaft and using larger diameter intermediate gear bearings. This increased the diameter of the gear requiring a different low range tooth count. In addition to the stock transfercases the Ashcroft high ratio transfercase is commonly found. I will explain the differences as I know them.

The gears and intermediate gear bearings used in the suffix A and B transfercases were discontinued decades ago and parts are very hard to locate. Some people still seek these out because they provide slightly lower low range ratios than the later transfercases.

It should be noted that the stock Series high range gearing is a 15% underdrive This is because the Land Rover engineers decided that their engines were not strong enough to push the common 1:1 transfercase high range ratio under all common driving conditions. Overdrives available for the Series transfercase boost the gearing to a 28% overdrive. This provides a higher gear ratio that can selectively be used under favorable highway conditions plus a third gear ratio between stock 3rd and 4th gears which is very useful during mountain driving. An overdrive adds a lot of flexibility for different driving conditions. The Ashcroft high ratio transfercase permanently replaces the high range ratio from a 15% underdrive to a 32% overdrive. If your engine can push this gearing it provides higher highway speeds for a given engine RPM. Many people with stock engines have found the new fourth gear ratio to be too high for many driving conditions. The Ashcroft high ratio transfercase is very useful for Land Rovers that have more powerful engines installed. I recommend against installing one to go behind a stock Series Land Rover engine. It should be noted that because the Ashcroft intermediate gear is relocated an Ashcroft high ratio transfercase cannot be used with an overdrive. It is either one or the other.

If you want to calculate the overall gear ratio at the axle you will need the gear ratio of the specific transmission gear, the ratio of the transfercase, and the ratio of the ring and pinion gear (4.7:1).

Stock transfercase

high range |

Fairey

overdrive |

Romerdrive

overdrive |

Ashcroft

high ratio |

1.15:1 |

0.78:1 |

0.8:1 |

0.87:1 |

To save you a calculation, the overall ratio of the stock transfercase high range plus the overdrive is 0.9 for the Fairey/Superwich overdrive and 0.92:1 with a Roamerdrive |

The Ashcroft high ratio transfercase assembly consists of a reworked transfercase housing minus the studs plus 3 gears, a new gearbox main shaft output gear, intermediate gear, and high range output gear. You reuse your low range output gear. You build up the new transfercase using parts from your old transfercase. The Ashcroft modified transfercase housing can be identified by the sleeves in the housing that relocates the intermediate gear shaft to compensate for the new gears.

The Ashcroft high ratio case can be identified by the sleeve at the intermittent gear shaft hole which relocates the shaft for the new gears. The stock C suffix and newer cases share the same intermediate gear shaft hole size as the Ashcroft case, 1.72 inches, while the early A & B cases have a 1.14 inch diameter hole for the intermediate gear shaft. The hole size & presence or absence of a sleeve is a quick way to identify which case is which.

|

| Tooth count for each gear |

| |

Gearbox mains haft output

gear |

Intermediate

gear |

High range output

gear |

Low range output

gear |

| Early stock |

31 |

44/22** |

31 |

40 |

| Late stock |

31 |

44/25 |

27 |

36* |

| Ashcroft Hi-Ratio |

31 |

44/22*** |

31 |

36* |

* Stock gear gets reused in Ashcroft high ratio transfercase

** Diameter of suffix A & B shaft/bearing hole in gear: 1-5/8 inches

*** Diameter of Ashcroft high ratio shaft bearing hole: 2-1/4 inches |

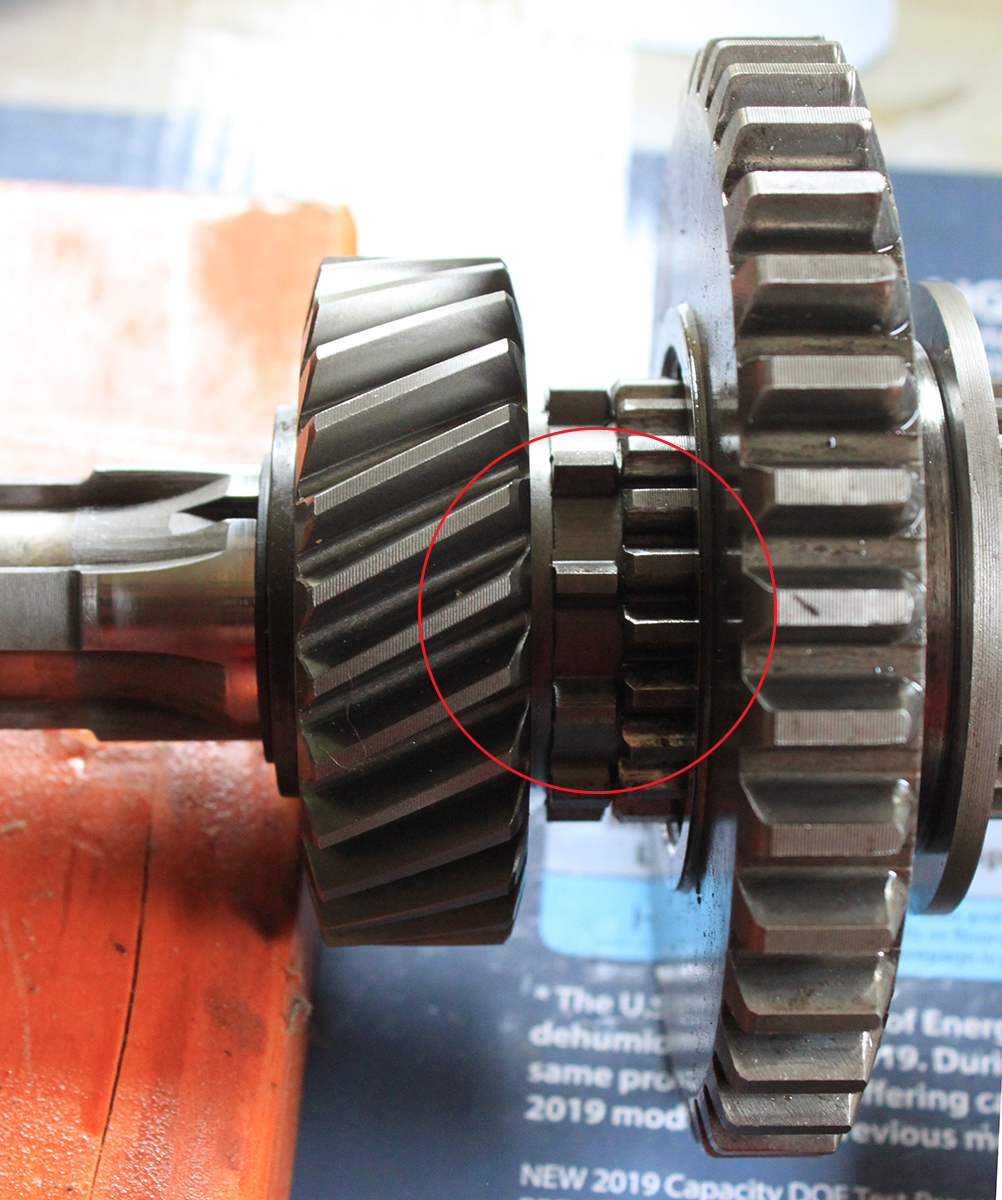

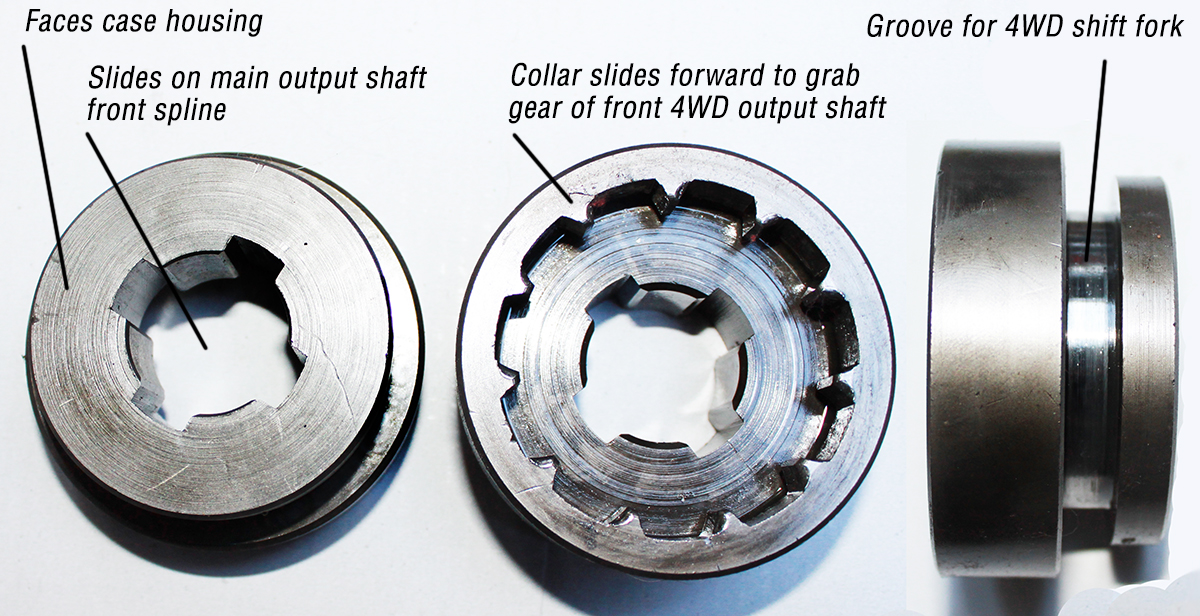

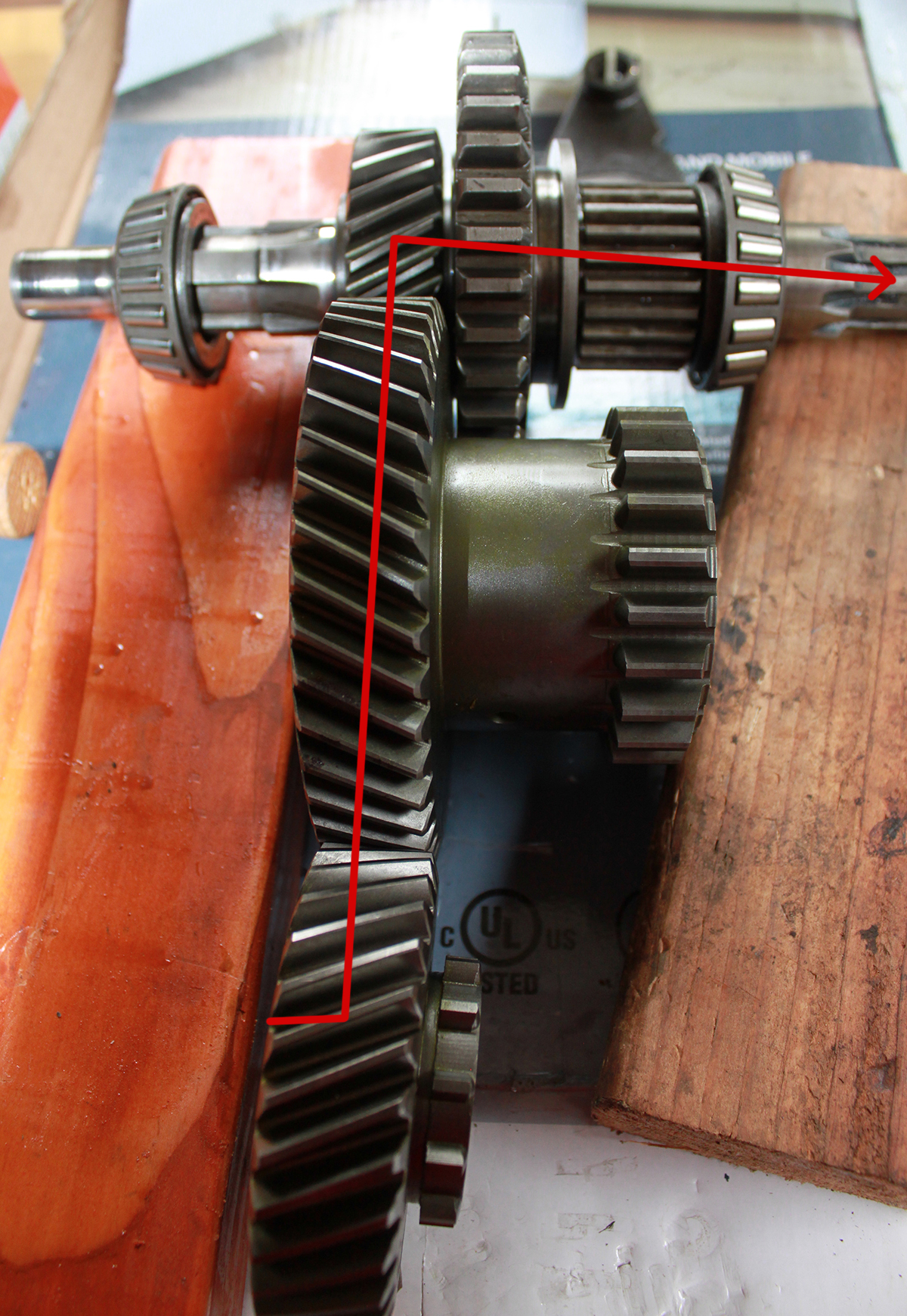

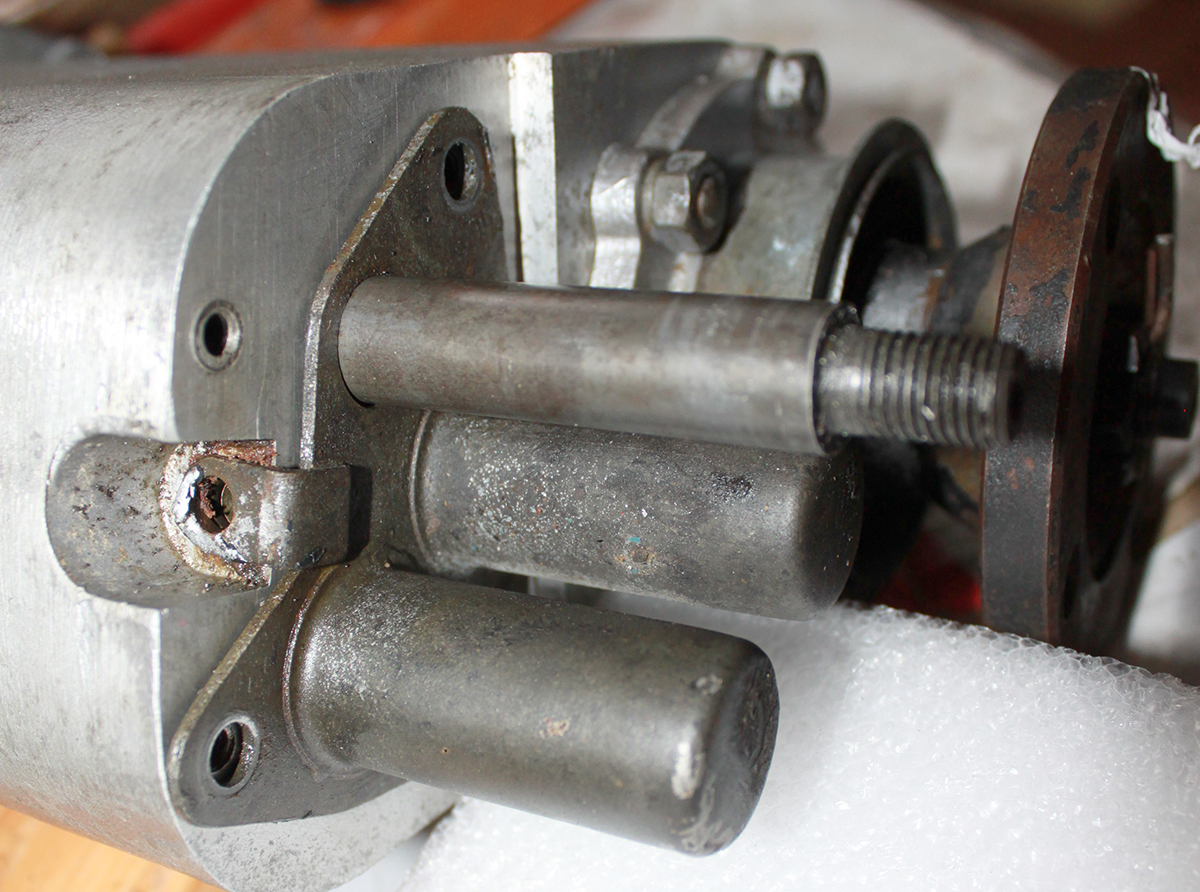

Transfercase gear set:

Left - gearbox main shaft output gear inside transfercase

Middle - intermediate gear

Right - assembled output shaft with high and low range gears

|

It is important to note that the high range gear (left) is not splined and rotates continuously without turning the transfercase output gear shaft. It is only when the low range gear is moved forward to cover the external splines on the side of the high range gear that the high range gear can turn the output shaft. The vehicle needs to be stopped and the clutch in before the spines can match up. The picture shows the gears in the low range position.

|

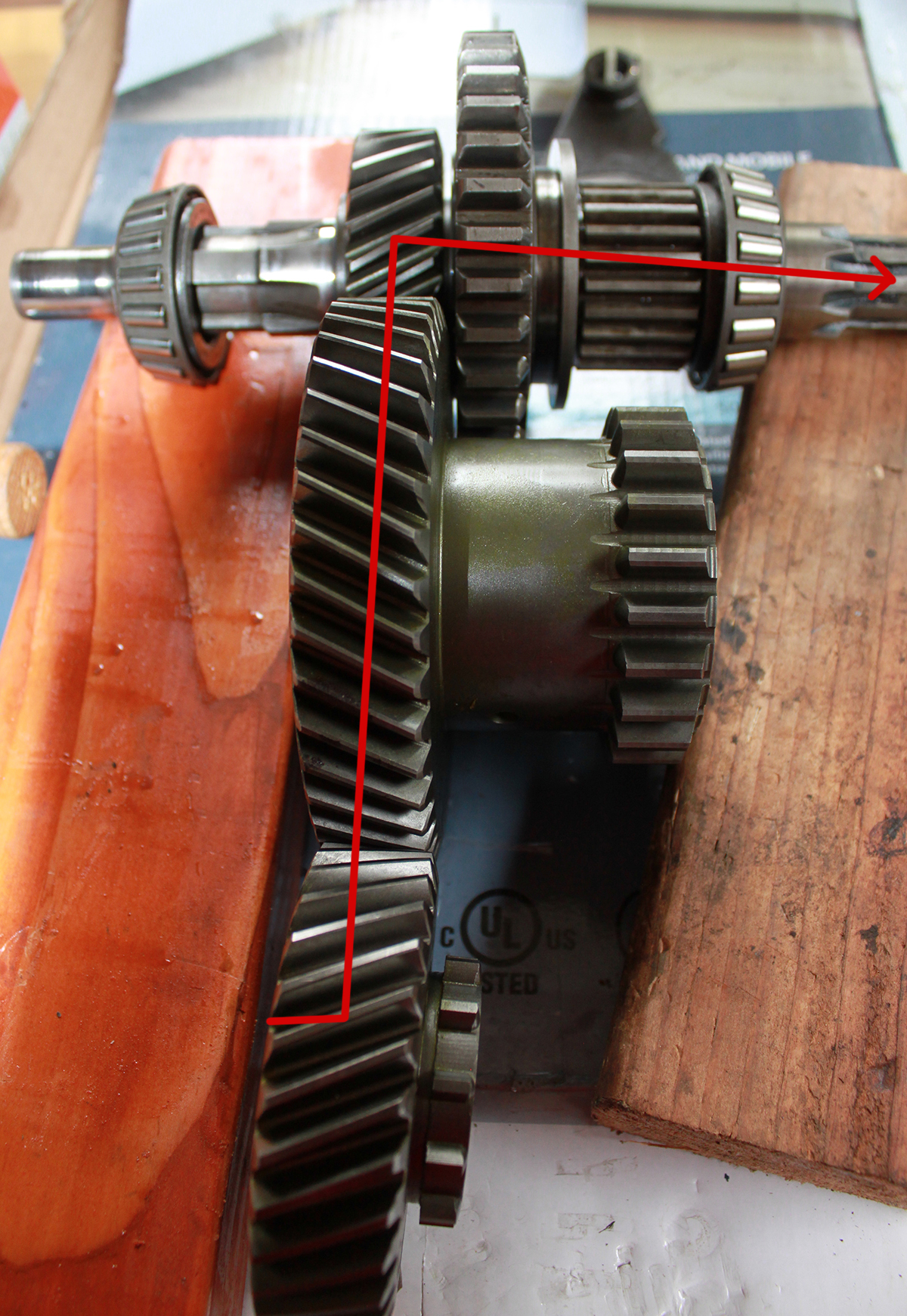

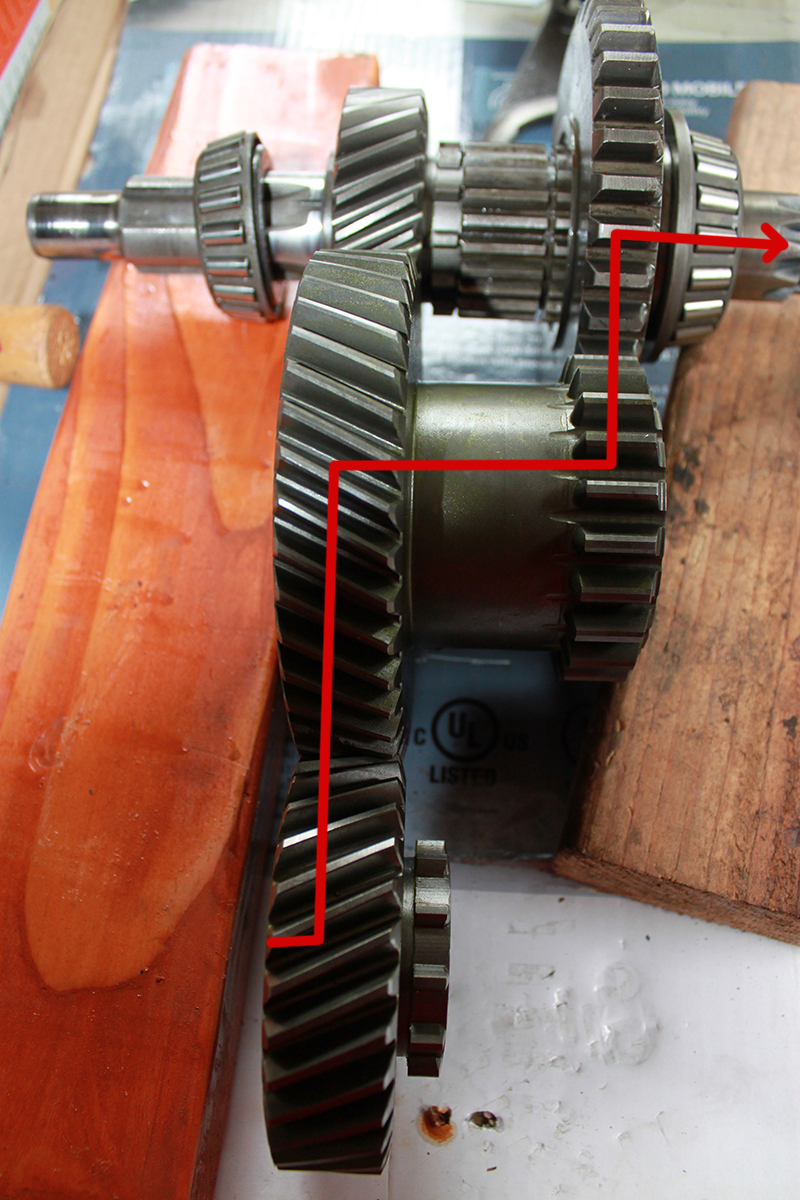

High range power flow

This is the power flow through the transfercase when the low range output gear is moved forward to engage the splines on the high range gear.

|

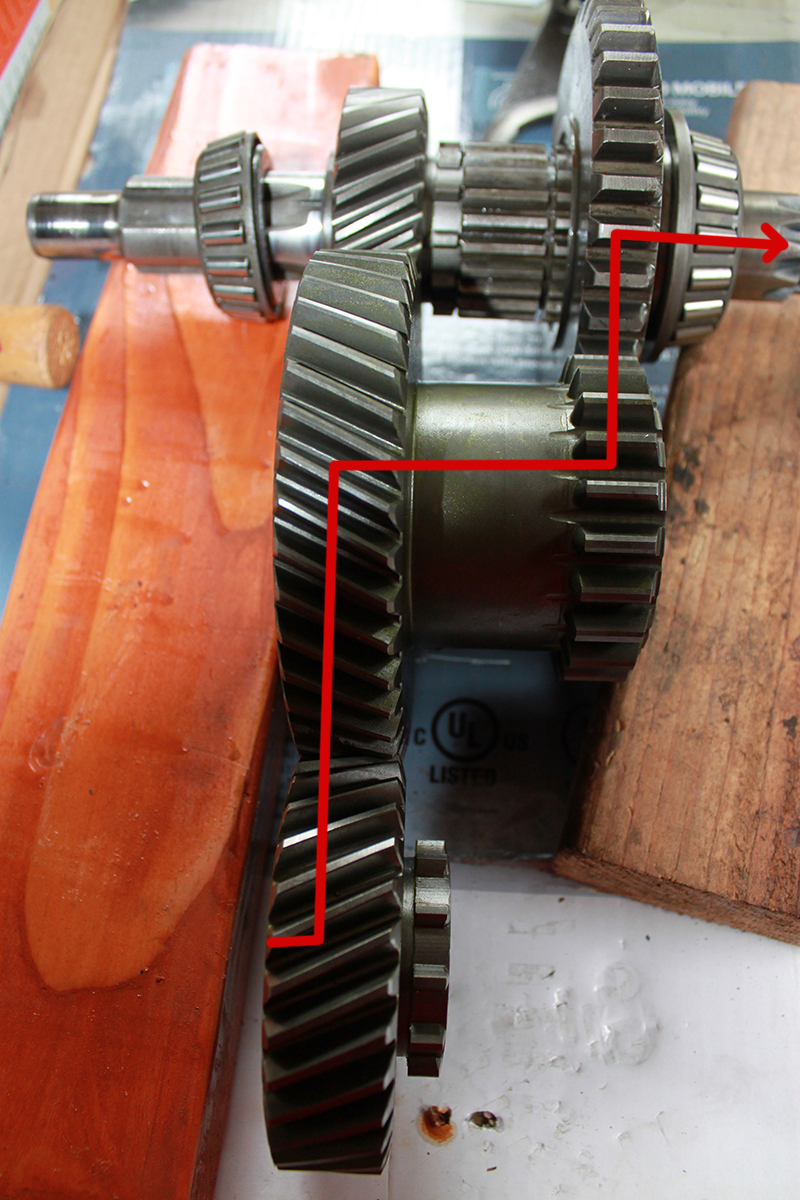

Low range power flow

This is the power flow through the gears in low range. Note that the high range output gear is always engaged with the intermediate gear but since it is not splined to the output shaft it spins freely.

NOTE - In the neutral shit position the low range gear is moved forward enough to no longer ride against the

low range gear on the intermediate shaft but not far enough forward to engage the side teeth

on the high range gear. |

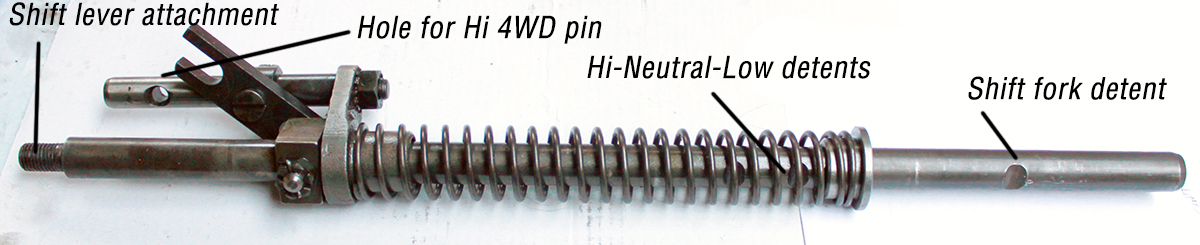

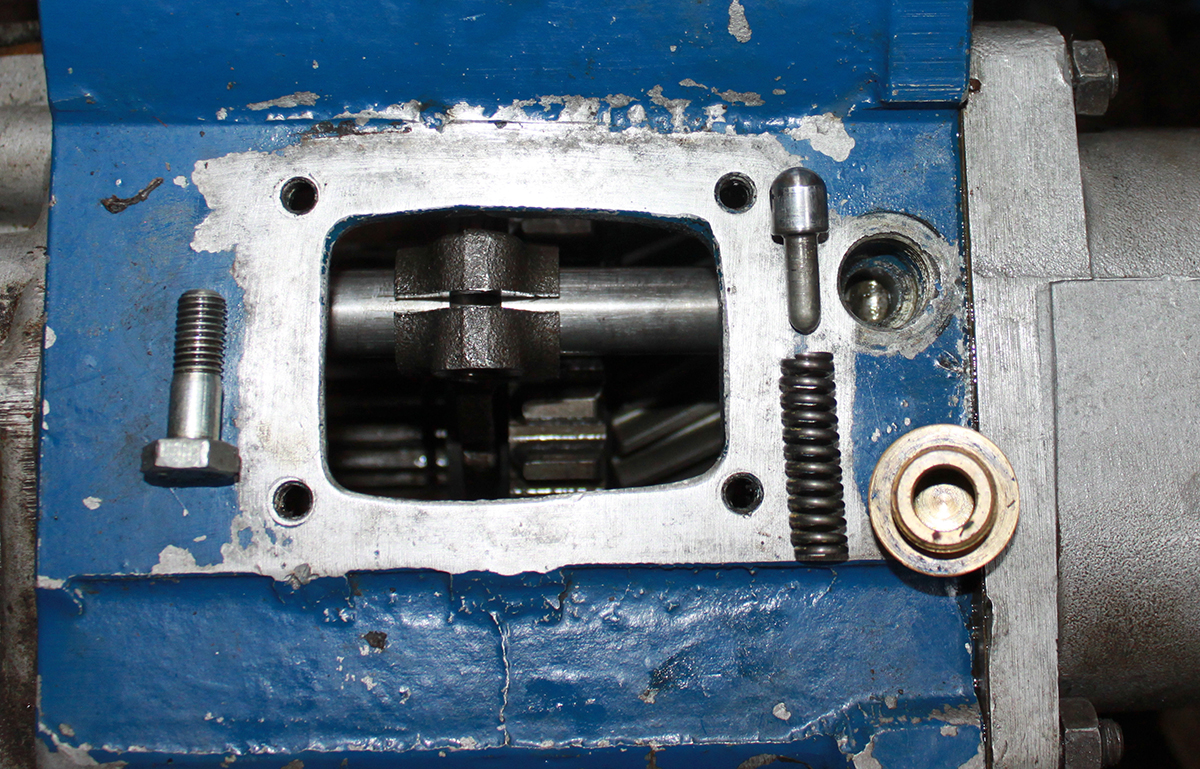

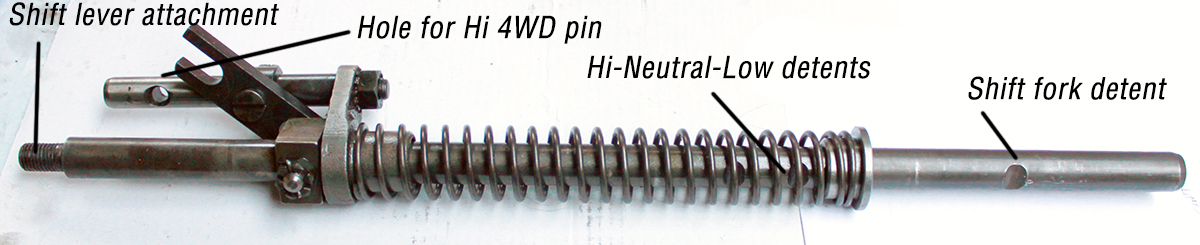

Special bolt to hold the shift lever mounts as shown with the head away from the gearbox

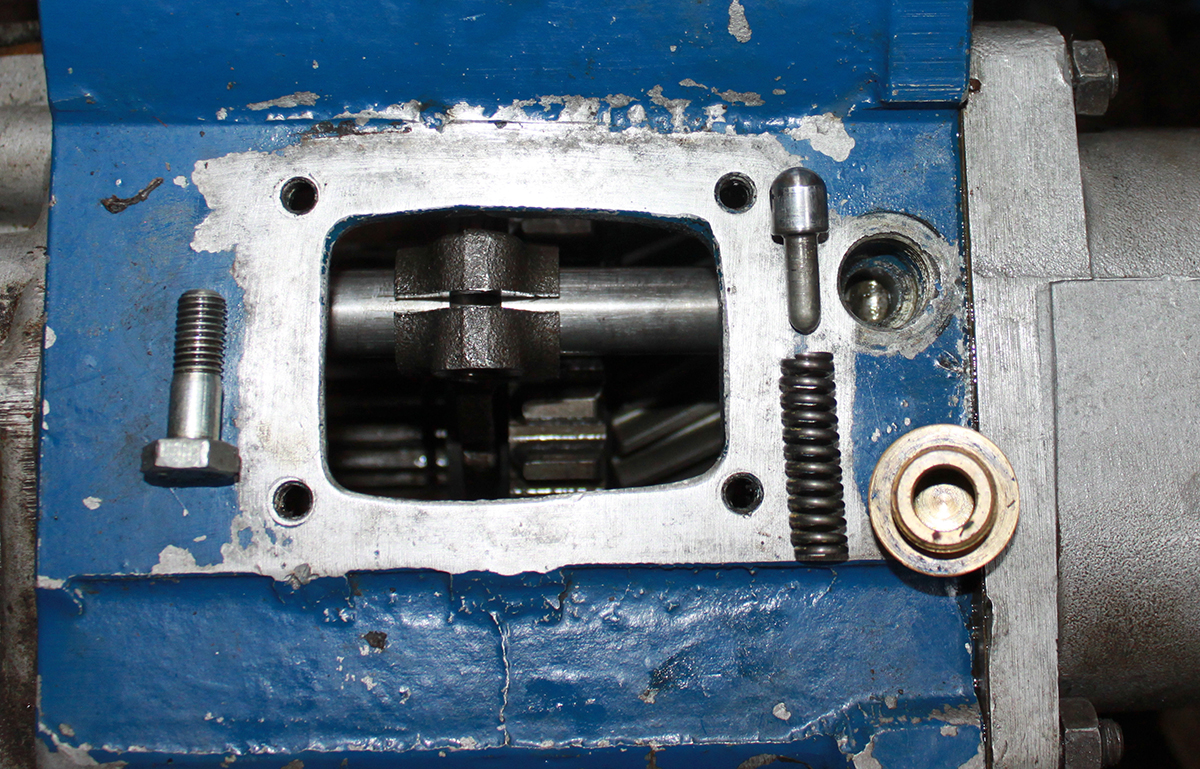

High low range shift rod detent assembly. The spring loaded plunger drops into the 3 detents on the shaft (high - neutral - low range)

If the transfercase pops out of gear it is almost always because the spring is too soft or a spring for the gearbox shift detents was accidentally used

during a rebuild (shift lever detent springs look the same but are weaker).

Order a new transfercase detent spring. A field fix is to shim the spring

by

placing 1 or 2 small washers inside the brass cap that holds the spring down. |

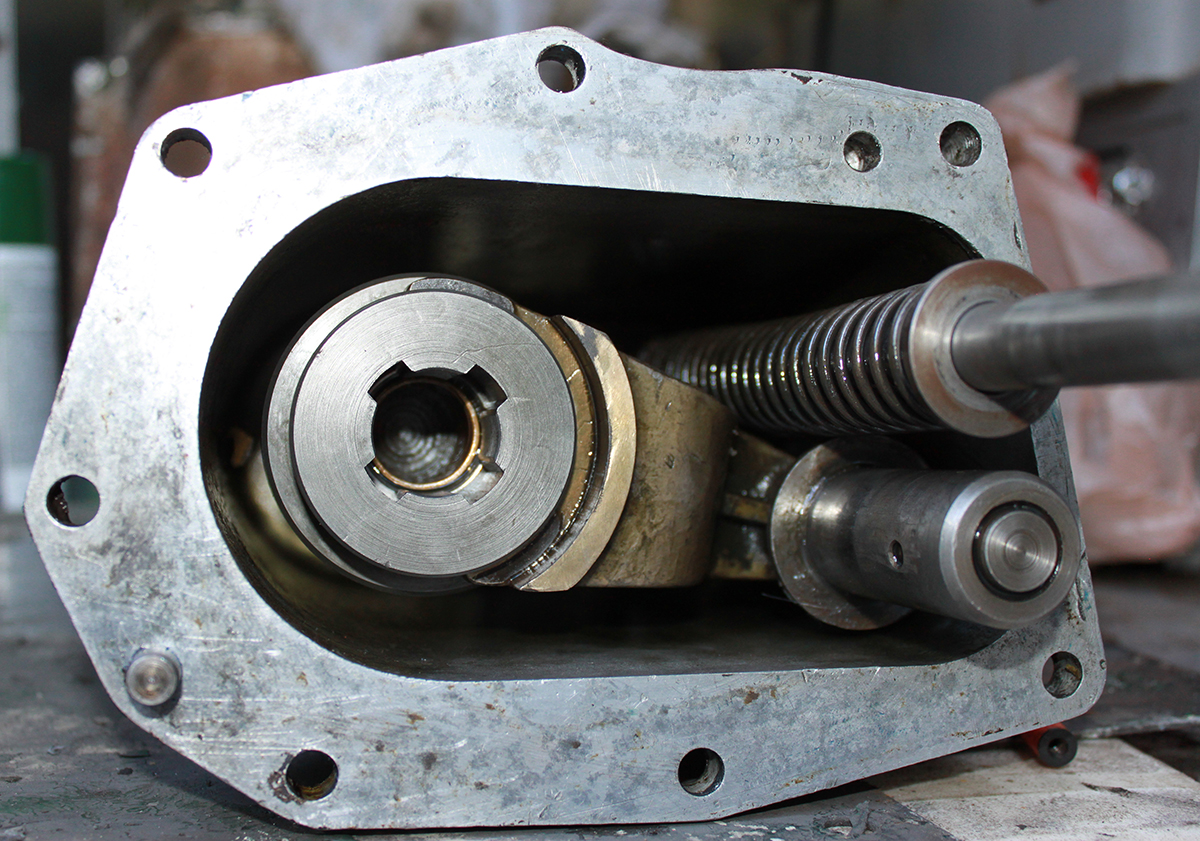

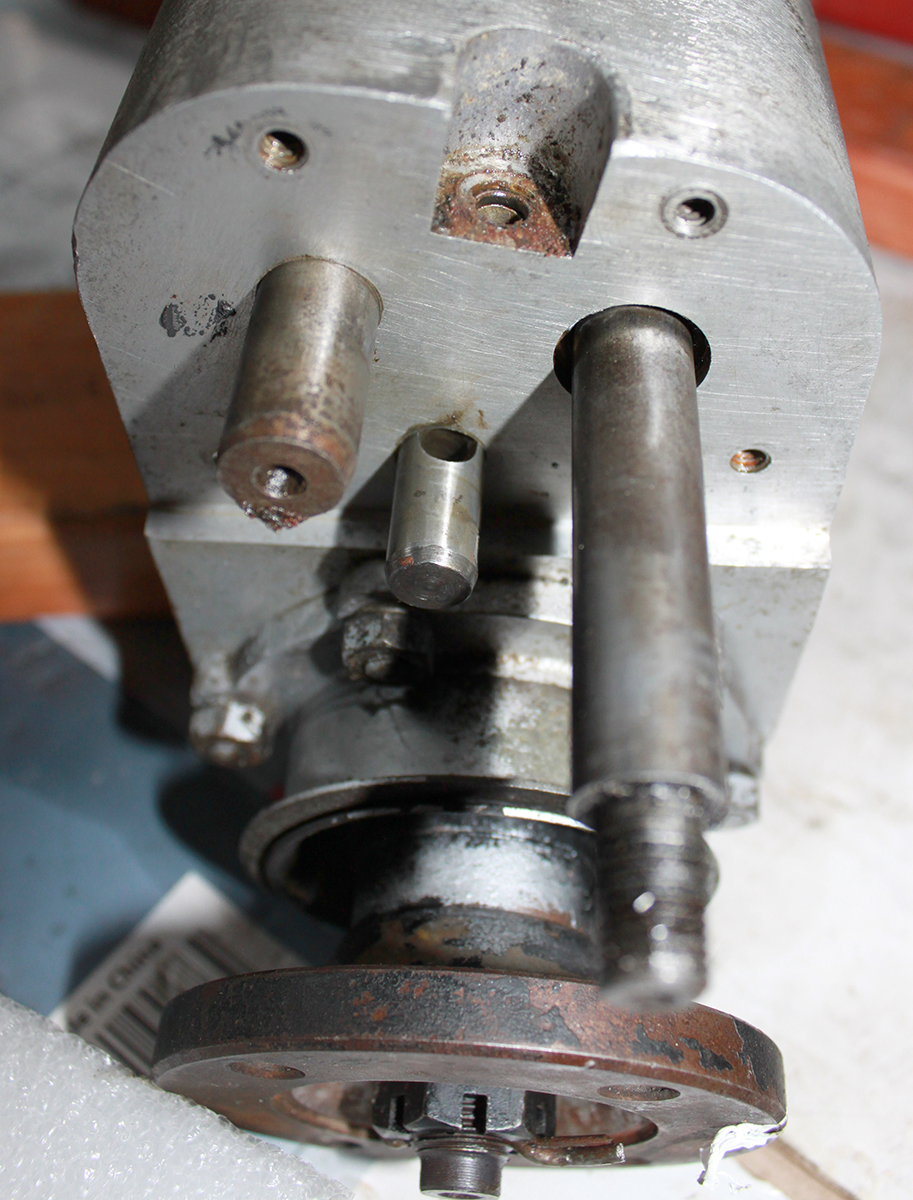

Front nose assembly

The main transfercase section contains all the gears and can shift between high range and low range, providing power to the rear axle assembly. The front nose assembly contains the front output shaft that provides power to the front axle assembly, the linkage shafts that shift the high and low range gears in the main transfercase and shifts the collar that engages 4WD.

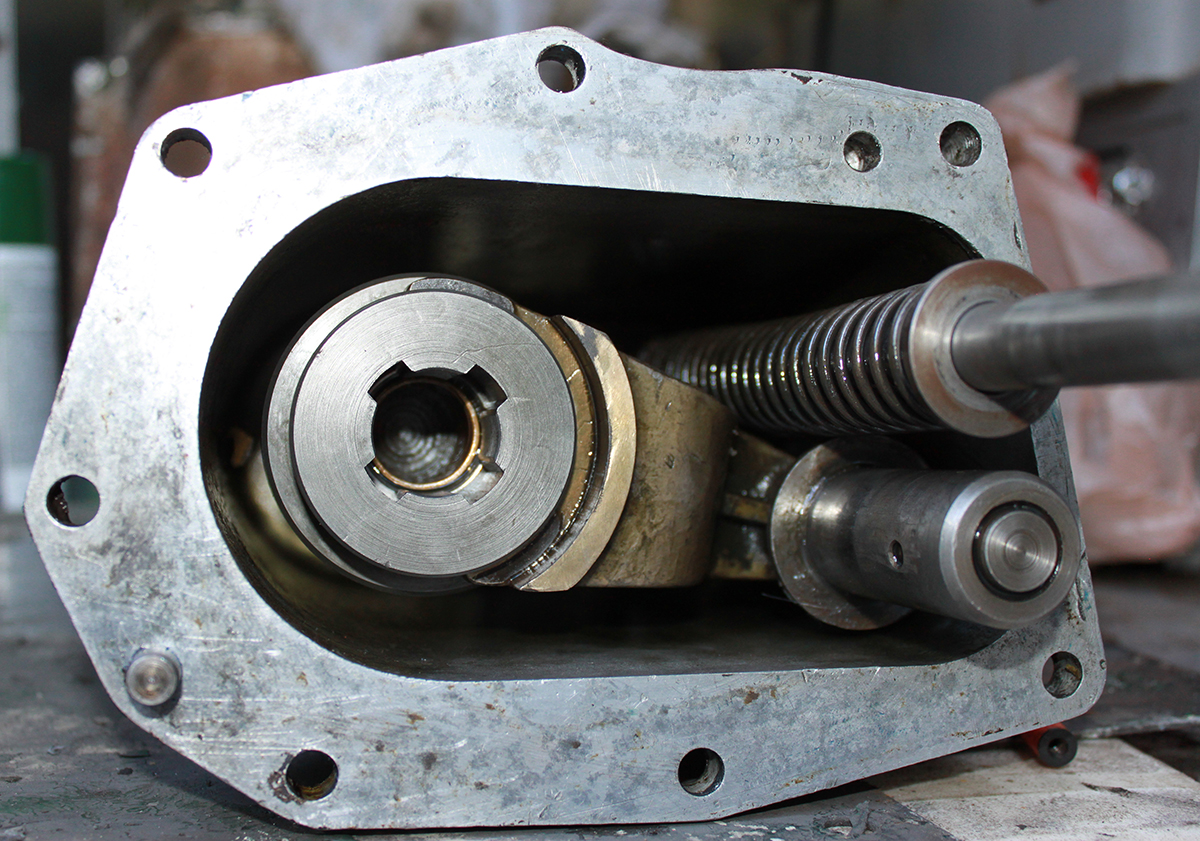

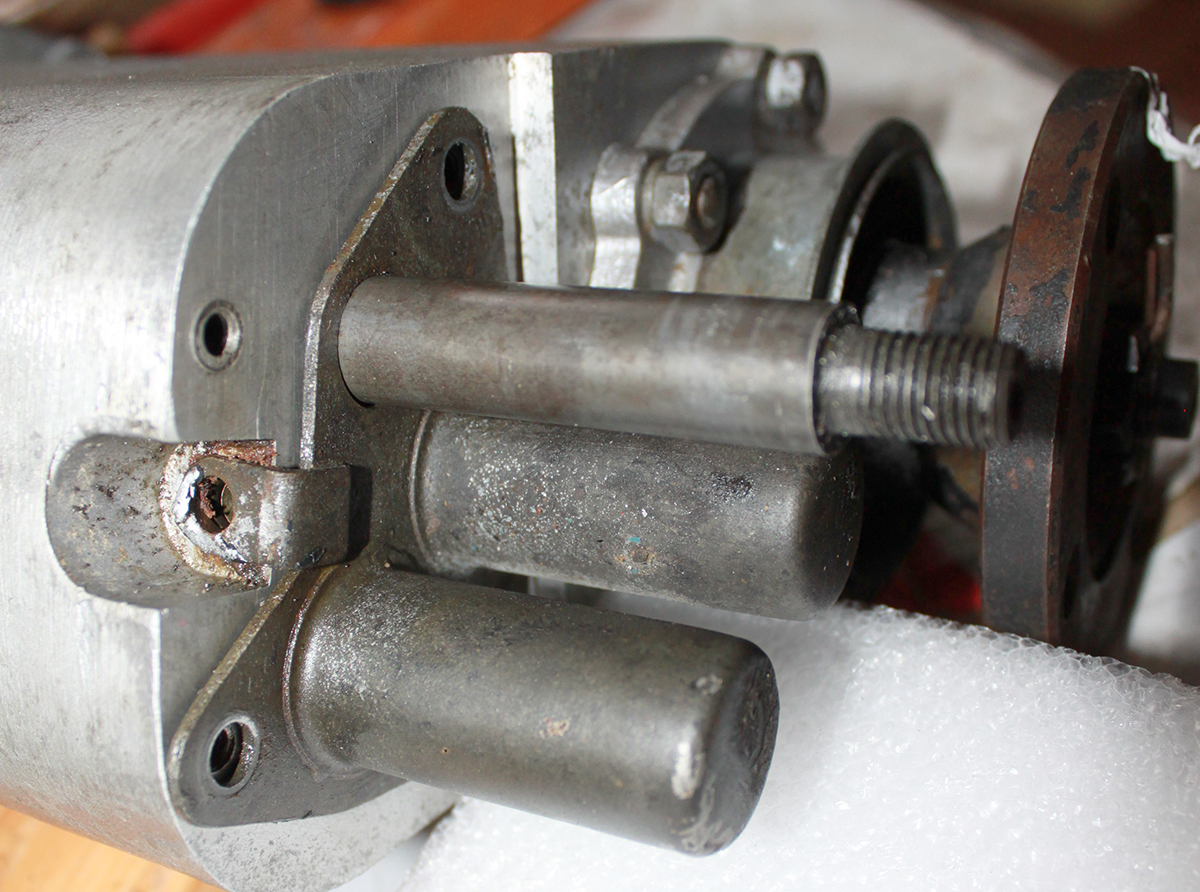

Inside the front nose assembly with everything assembled ready to be attached to the rear case.

|

Shows the front output shaft and the front bearing it rides in.

The gear at the near end of the shaft is what the collar engages when it is pushed forward into the 4WD position.

There is a bronze bushing in the centre hole. The nose of the rear output shaft fits into this hole aligning both

front and rear shafts.

Since GL-5 attacks bronze, this is why you want to use GL-4 gear oil in the transfercase.

|

These are the shift rods that fit inside the the nose piece as you would see them if you could look

down into the case

|

The internal shift rod that selects high and low range

There is a spring loaded plunger that rides against the shaft and locks into the detents to hold the rod in position.

If a transfercase pops out of gear it is usually a symptom that the spring is too weak or the wrong

spring was fitted during a gearbox rebuild.

|

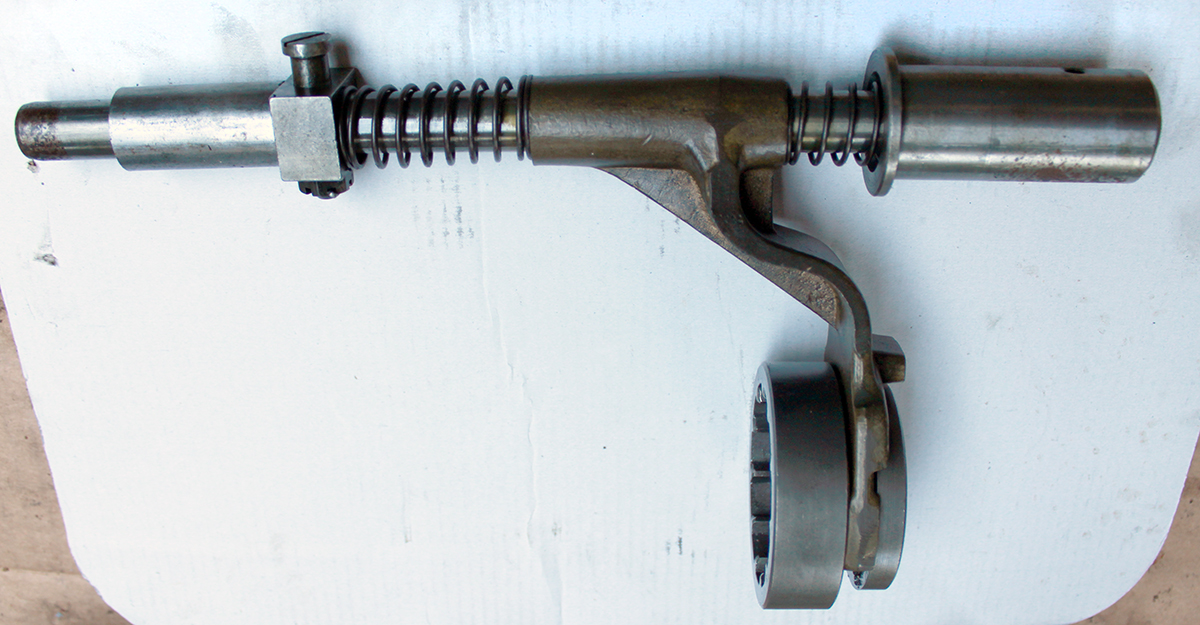

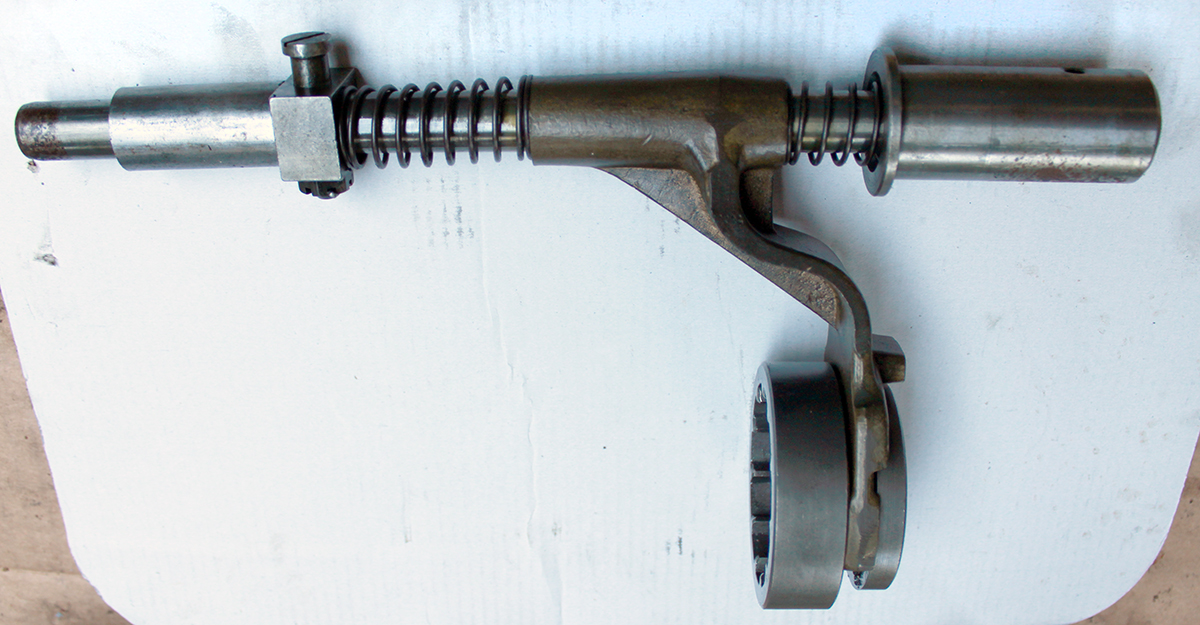

The internal 2WD-4WD shift rod with collar mounted.

When the red knob shift lever is in 2WD the collar is back against the front wall of the main case.

When the internal shift rod is pulled into the low range position this rod gets moved forward causing

the collar forward to engage the front shaft gear.

|

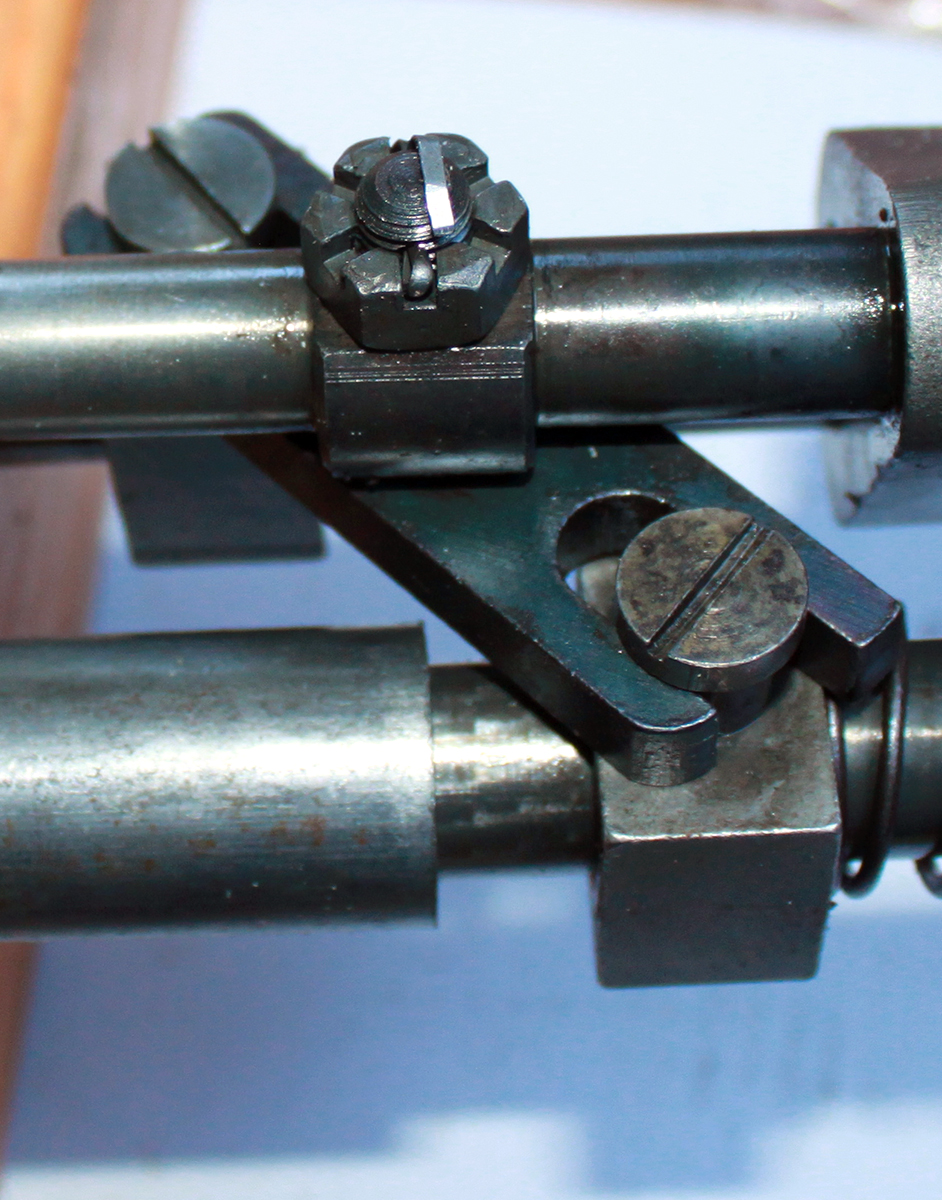

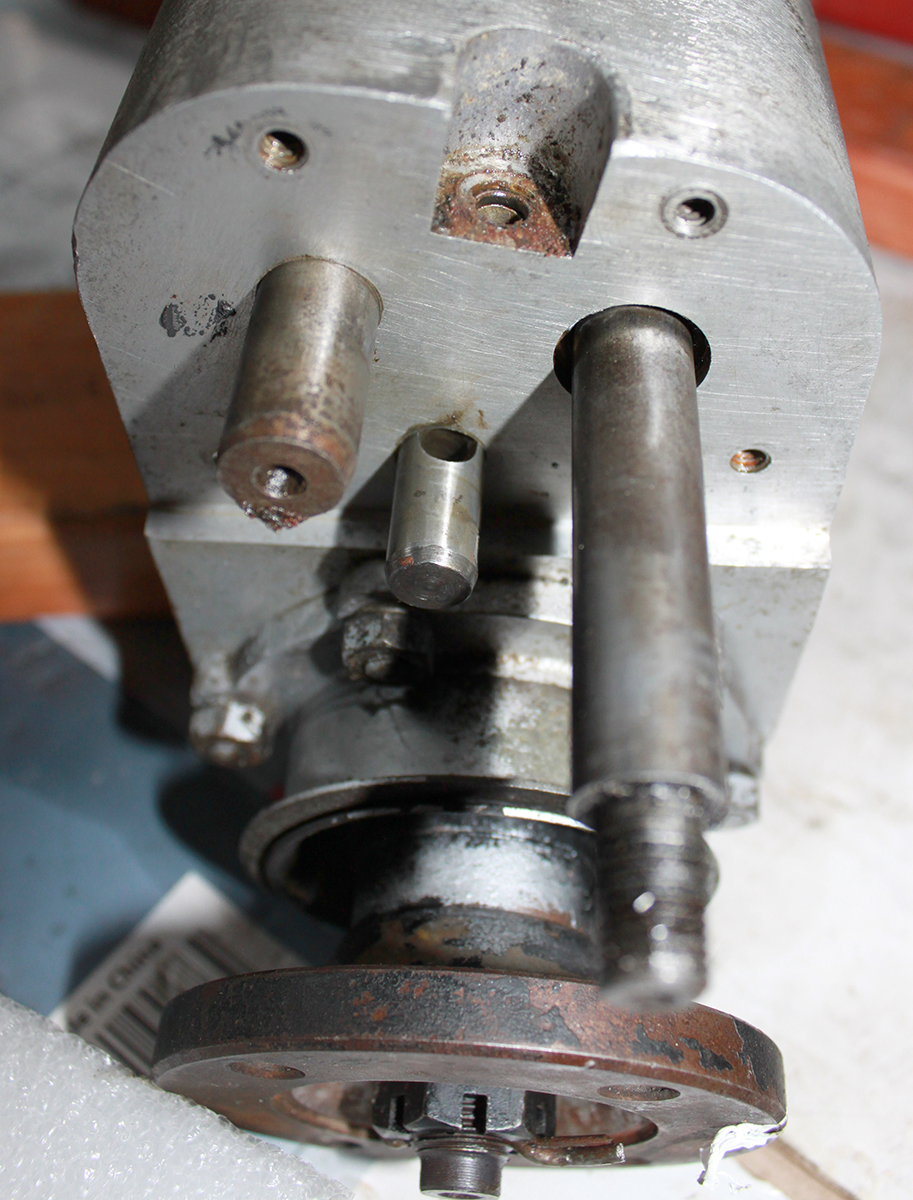

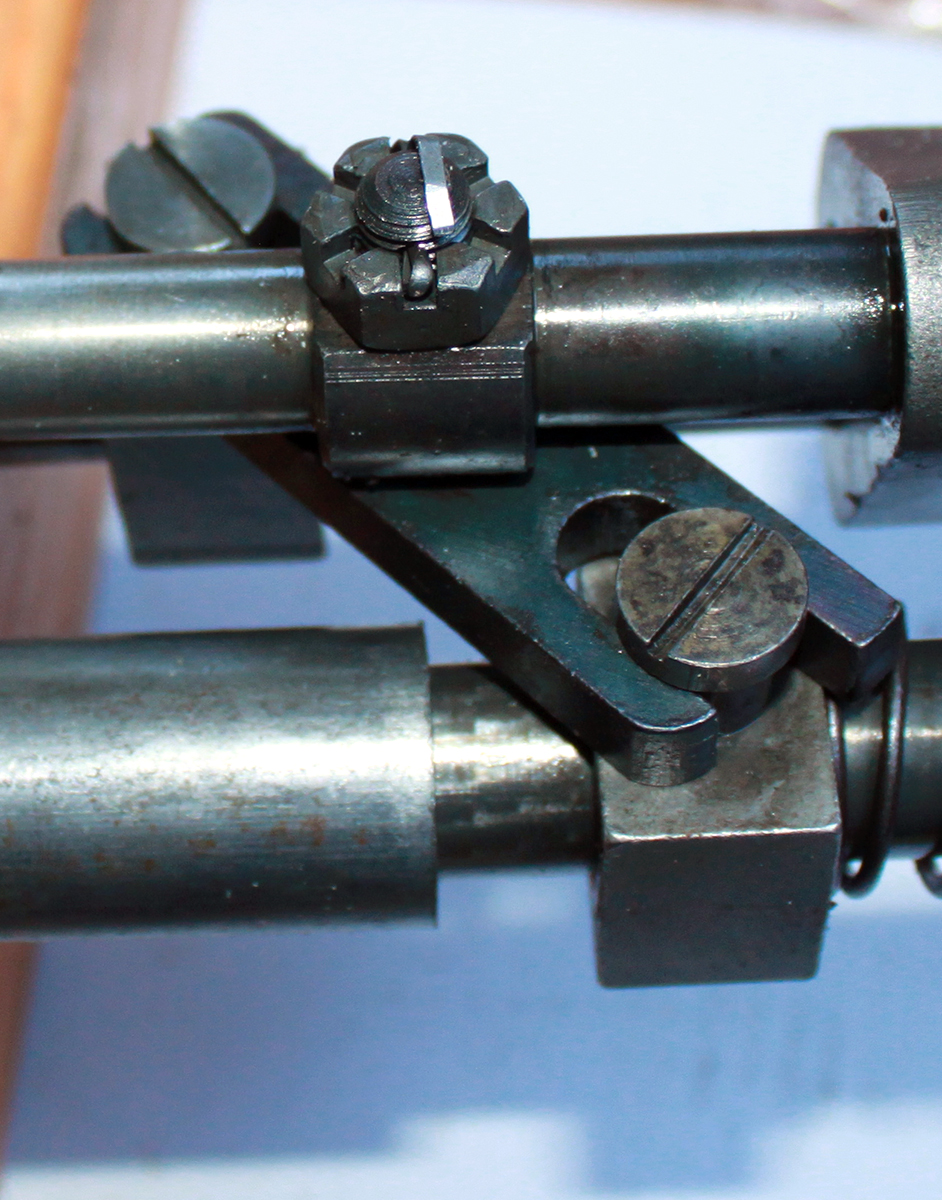

The cross shaft as seen from below that moves the shorter shift arm in relation to the long arm. The cross shaft is bolted to the

short centre shaft that has the hole for the high range 4WD pin. This shaft is mounted to the long shift rod. When you shift into

low range that lever pulls the shaft holding the collar gear forward to engage the front wheel drive shaft.

When the high range 4WD rod (yellow knob) is pushed down a pin is lifted out of the short centre rod which moves to pull the shaft with the collar gear mounted

forward into high range 4WD. (moves one rod without moving the other)

When installing the nose piece care should be taken not to pull one rod in relation to the other as a shift pin can be pulled out of the cross shaft. The

box will not go into 4WD if a pin is out of the shaft.

|

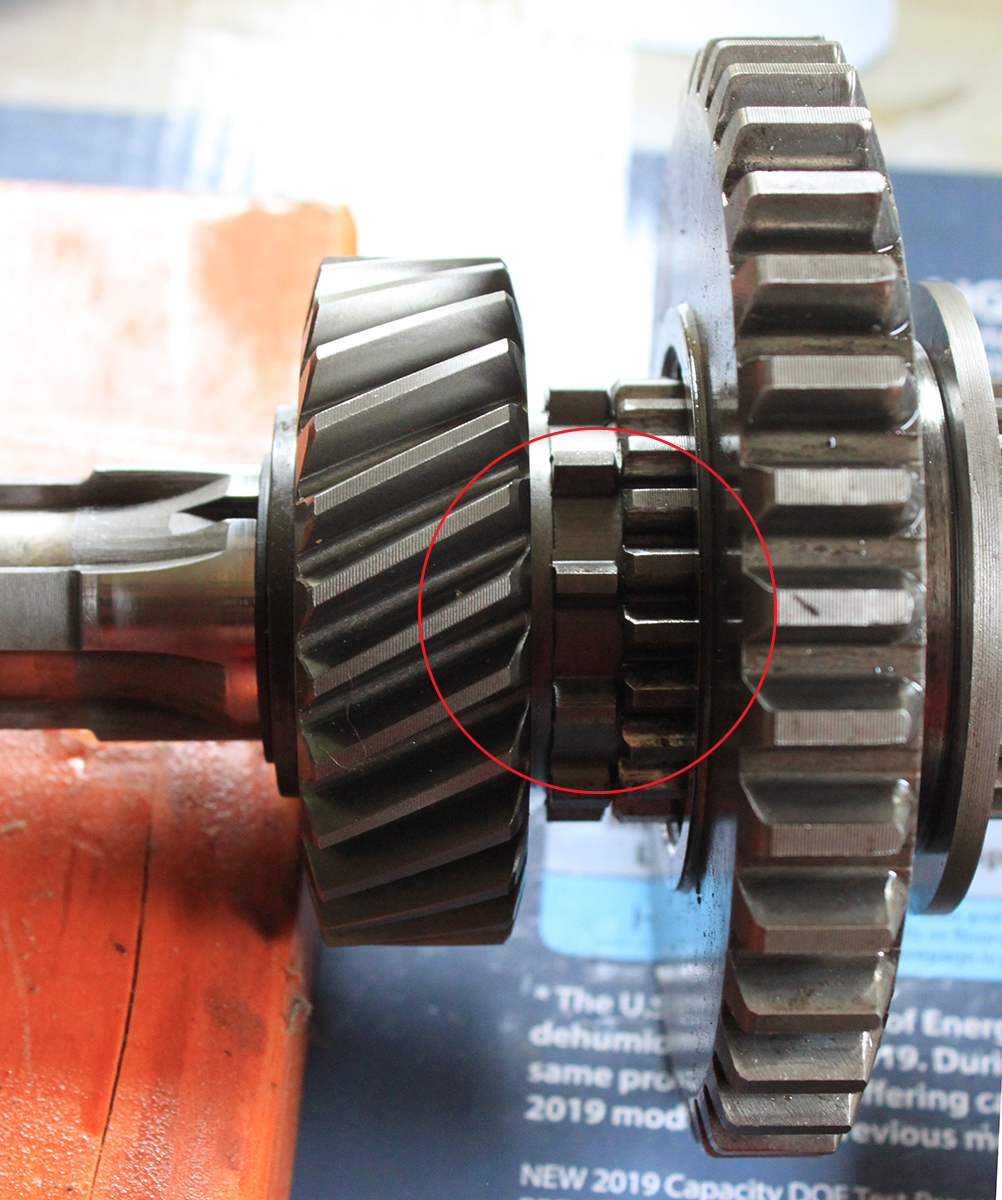

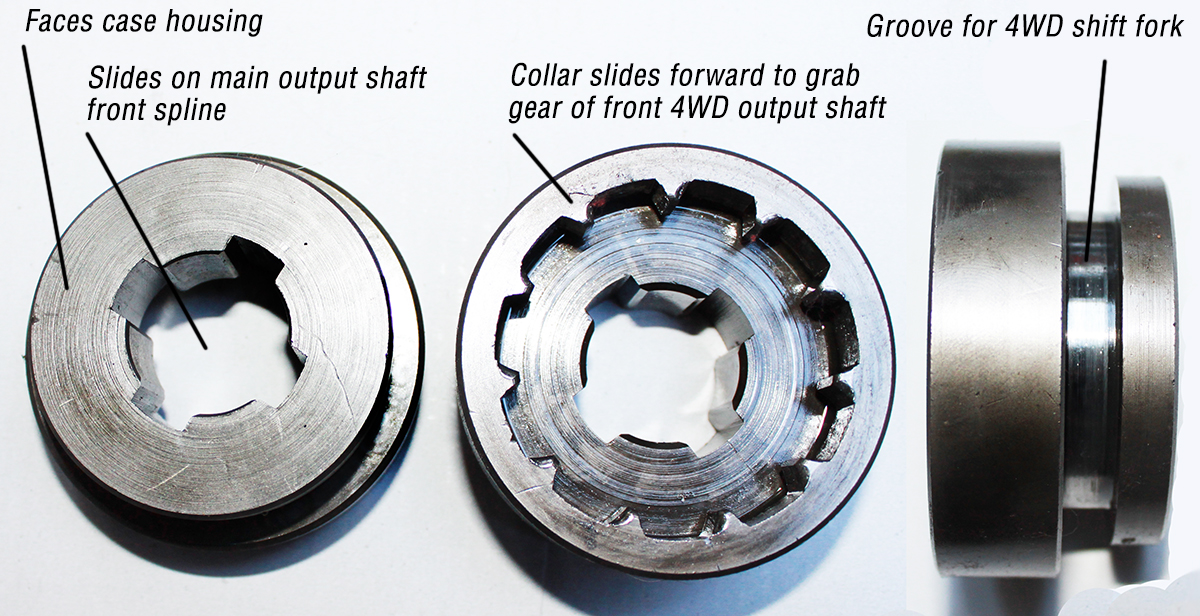

Collar that engages the front axle assembly for 4WD.

In 2WD the collar rides against the front of the main case, spinning on the rear output shaft splines,

but not touching the gear on the front output shaft. When you shift into 4WD the collar moves forward

to engage the gear on the front shaft while still attached to the rear main output shaft splines. This locks the 2 shafts together.

|

Rarely, if the Land Rover has sat unmoving for years you might find that the transfercase has decided not to shift into 4WD

When a transfercase that functioned properly before being parked no longer shifts into 4WD it may be because the 4WD shafts are frozen in the holes of the transfercase nose piece. Possibly because of a rust build up at the front keeping them from moving into the holes in the case or more likely because of lubricants drying out and freezing them in the holes

This sheet metal cover covers the ends of the 4WD shifting shafts. A sealant should be used to keep water out when wading.

|

With the sheet metal cover off you can see the two shafts (middle & left) that moves the fork that shifts the transfercase into 4WD.

These shafts are spring loaded so if they are frozen the high/ low range shifter will not shift the box into 4WD.

Heavy rust or dry grease can cause these shafts to freeze in their holes. If it is caused by dry grease, some solvent spray and

gentle tapping should free them up and allow the transfercase to work properly.

|

There is an excellent pictorial guide to rebuilding a Series III gearbox and transfercase on a French web site. It is in French but it has excellent step by step pictures that speak for themselves.

Return to page top

|