|

Thoughts about Land Rover shocksThe Shocking limits of Land Rover leaf spring articulationWhat follows are my personal thoughts and current understanding on the subject of series Land Rover shock absorbers and how they affect spring articulation. Please do not let them limit your thinking if you are contemplating something substantially different and innovative. Before going into this discussion I should state up front that the #1 limitation to series Land Rover suspension articulation is shock length and the only way to get beyond that limit is to move the top and bottom mounts farther apart and install longer shocks. There is no way around this

Dampening The purpose of shock absorbers is not to absorb shocks. What they do is provide a resistance to the spring's movement that dampens spring oscillation. Without a shock if a spring is deflected then allowed to freely return to its rest location the momentum of the spring mass carries it past the rest point then back again past its rest point in oscillation. The shock exists to dampen this spring osculation so the driver does not feel like a jack in the box head on the end of a just released spring. Shocks work most effectively when the dampening resistance is matched to the oscillating characteristics of a spring and when the shock is aligned perpendicular to the movement of the spring. Some of the spring movement energy absorbed by the shock turns into heat. Shocks heat up during off road use and more so in fast off road use. The hotter they get the less effective they become at dampening oscillations. There are a number of approaches to handling this heat and minimizing shock fade, including using multiple shocks. Shock absorber manufacturers are constantly researching new and better ways of handling heat and shock fade then offering socks with their latest technology. I will not go into dampening levels and heat dissipation. This is one place where you need to check a manufacturer's current product line for the characteristics you need when you go to purchase shocks. If you are going to drive washboard roads at speed, look into a shock's resistance to heat fade. For most slow cross country trailing the common nitrocharger style will usually do the job without fade issues. Land Rover shock absorbers work just fine on stock Land Rovers operating within the Rover engineer's design parameters. They did a very good job of matching shock characteristics to the springs they specified. If you are running a basically stock suspension system with factory specified spring rates you would be hard pressed to find better than the original stock shock absorbers. However if you modify the spring characteristics or replace your springs with non Land Rover springs such as parabolic springs you may need to likewise modify your shock characteristics to better match the springs. Stock Land Rover shocks are not a good match for parabolic springs. Most companies offering a parabolic spring have tried different shocks that fit series Land Rovers and have determined which of the bunch works best with their parabolic springs. If you decide to install parabolic springs be sure to get the shock absorbers that the company recommends to use with their shocks. They have done the research which can save you from costly trial and error efforts.

Series shock length limits spring articulation Shock absorbers have a fully extended length and a fully compressed length. No amount of spring manipulation can achieve articulation greater than the distance between a shock's travel between its top and lower limits in its mounted orientation. Unfortunately series Land Rovers have one of the shortest shock travel lengths of any off road vehicle. You can increase upper OR lower articulation at the expense of articulation in the other direction by choosing shocks with different compressed and expanded lengths. Since there is only so much distance between the upper and lower shock mounts aftermarket shocks can not extend total articulation over stock shocks. All they do is move articulation higher or lower a couple inches at the most. Some manufacturers or retailers of aftermarket shocks for series Land Rover claim increased articulation. What they really mean is that they have increased lower articulation at the expense of upward articulation. They have a longer extension rod which allows a spring to extend farther downwards but that longer arm creates a longer compressed length which hurts upwards articulation. The upper articulation stop should be the frame mounted bump stop and not the compressed length of the shock absorber. If you go to an aftermarket shock that has a longer compressed length you will want to increase the length of the frame bump stop. The frame bumper should come into contact with the axle housing at least a half inch before the shock reaches full compression. This allows some space for rubber compression. If you are playing around with the new poly stops, use the manufacturer's recommendations. Most of the poly stops I have seen are designed to absorb the shock of contact by compressing to a greater degree than a solid rubber block. Most people don't pay much attention to upper articulation. It is the downward articulation that is visible and that people concentrate on. Here are two reasons to pay attention to upward articulation. 1. The more that axle movement conforms to uneven terrain the more level the vehicle is likely to sit. Imagine a vehicle without a suspension system. The axle housings bolted directly to the frame. If a wheel is unsupported, the body tends to remain in line with the other three wheels for as long as the other three wheels support the vehicle's centre of gravity. However any bump that moves any of the four wheels upward will push the vehicle upward at that corner and force one wheel off the ground. The ability of a suspension to articulate upward is a critical factor in keeping a vehicle level and the other three wheels in contact with the ground. The greater the upward articulation capability, the more stable a vehicle is whilst rock crawling. The ability of a suspension to articulate a wheel downward affects the ability of that wheel to get enough traction to help propel the vehicle forward and how abruptly the body tilts if the vehicle's centre of gravity is no longer supported by the other three wheels. Of course with an open diff, loss of traction on one wheel spells loss or power to both wheels on the axle. 2. On solid axle vehicles, the greater the articulation on one side, the greater the articulation at the other side as long as the limits of articulation are not reached. When an axle is on an uneven surface, the forces acting to articulate one side of the axle act to increase opposite direction articulation at the other side. Articulation is enhanced when one side encounters a bump and the other a trough until an articulation limit is reached at one side or the other. Increasing lower articulation at the price of upward articulation will not increase the axle assemblies total articulation and it will make the vehicle a tad less stable under rock crawling types of conditions.

Increased articulation through longer shocks The shock absorber ties the frame to the end of the axle housing. Land Rover shocks are mounted in the direction of spring travel for maximum dampening affect. Without changing orientation, the extended length of the shock absorber will set the lower limit to articulation and the length of the compressed shock will set the upper limit of articulation. If you add a shock with a longer rod, the compressed length will be longer. If you wish to achieve greater overall articulation you will need to move the shock mounts and fit a shock with longer travel. Rover suspension engineers did just that when Land rovers went to coil springs. A very important part of the reason that stock coil sprung Land Rovers have greater articulation than leaf sprung Land Rovers is that the coil sprung vehicles have more shock travel. Parabolic or low friction elliptic leaf springs alone will just let you get to the limits of shock travel quickly if you do not extend them. They will not increase articulation unless the leaves on the old springs were rusted together. Front shocks are easy to extend just by using the same bottom mounts and creating new top mounts.

With some modification, Toyota FJ40 and Ford F250 front top shock mounts would be good bolt/weld on premade top mounts for front shocks. The key is to keep the mount and shock as close to the frame as possible since the tyre top swings inward during upper articulation. Extension of rear shocks is more difficult because there is less space in the stock shock orientation. The easy solution for a short shock extension is to adapt Land Rover coiler rear top mounts. But without Defender lower mount points the added shock length is minimal.

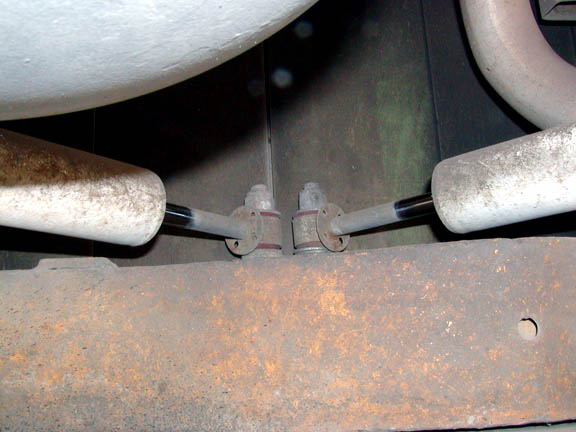

An approach many vehicle manufacturers make to deal with limited space in the direction of spring travel is to mount the shock at an angle to the direction of spring travel. The advantage of this approach is that the shock needs to extend or compress less for a given amount of spring movement. The disadvantage is that as you move the shock travel farther away from the direction of spring travel the less effective it is. You can compensate with a higher dampening rate on the shock. A common rear shock mounting arrangement on leaf sprung 4WD vehicles is to angle the top mounts inwards towards each other. This allows longer shocks to be fitted than there would otherwise be space for. This in turn allows the springs to articulate to a greater degree without being stopped by a shock that reached the end of it's movement.

The Toyota FJ 40 rear shock mounting is this style and can easily be reproduced at the rear of a series Land Rover. Some years of FJ40 have bottom spring plates with a built in bottom shock mount. These can be used at the rear of a series Land Rover along with larger diameter 'U' bolts. The upper mount can be either an inverted 'U' channel or 'L' channel welded between the frame rails at the tops and drilled for upper shock mounting bolts. If you place the top cross member and mounting holes so that the distance between upper and lower mounts are the same as an FJ40, you can use the variety of off the shelf available FJ40 rear shocks. Otherwise you will need to measure shocks to fit your application and hope to get one with heavy enough dampening for your application. A couple thoughts about inward tilting shocks. The closer towards horizontal they are mounted the less effective they will be, so placing the top mounts together at the middle of the cross member may not be the most effective solution. The closer you can get them to vertical and not interfere with the frame during extreme articulation, the less dampening they need to be effective with your rear springs. Also when you angle a shock towards the middle it becomes a factor in dynamic body lean tending to dampen body movement the same way it dampens spring movement. I suspect that if you drew a line between the bottom rear shock mount of a factory stock FJ40 and the roll centre axis, the rear shock extension rod would be aligned along that line. Choosing shocks If you need to choose new shocks for your vehicle you will need to measure the distance between shock mounts at both upper and lower maximum articulation. . The maximum upper articulation can be the difference between the static mount to mount distance and the distance between the frame bumper and axle where the bumper would contact. Then subtract an inch for bumper stop compression. You need a ramp of some kind to measure the static maximum downward articulation. With the shock removed so it can not limit travel, measure the distance between the shock mounts when the wheel is off the ground and the end weight is supported by the upwardly compressed other wheel. Do not just jack up the front end so both wheels are off the ground. Add 2 or 3 inches to the static length to approximate a dynamic length. Your proper shock length will be where the compressed shock length is equal to or shorter than the upper articulation length and the fully extended shock length is equal to or longer than the calculated dynamic downward articulation. If you can identify a 4WD vehicle with similar shock length requirements, axle weight and shock mounting angle as your Land Rover you can use the shocks for that 4WD and be confident that the shock valving is close to what your Rover needs. Axle weight and shock mounting is one of the reasons I keep referring to the FJ40 as a model. If you duplicate the FJ40's shock mounting, which is much better than a Land Rover's, the weight is similar enough that the range of off the shelf specialty shocks for the FJ 40 would also me a good match for the Land Rover. If you can not locate a leaf sprung 4WD vehicle with the same approximate axle weight, get shocks with dialable shock resistance and experiment. And do not forget every change affects something else to a degree. Pay particular attention to front and rear propshaft to frame interference, length of flexible brake lines, propshaft lengths at both upper and lower maximum articulation and 'U' joint binding. One change will often require a number of other changes to bring everything back into acceptable specs. Be careful...be aware..be safe. |

|

If you would like to discuss any of the contents, or just say hi, please feel free to .

© 1997, 2001, 2017 TeriAnn Wakeman. All rights reserved. |