|

Halogen lamps throw out a lot more light than the Series Land Rover's original tungsten filament headlamps and are an important upgrade for any Series Land ROver that ventures out after dark. Contents

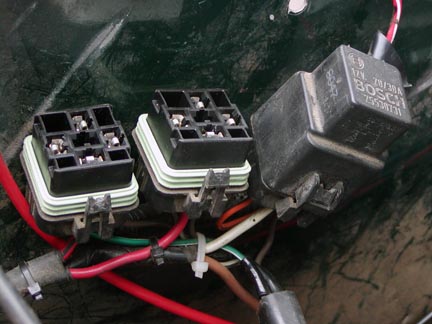

Converting to same wattage Halogen lampsConverting to Halogen headlamps with the same high and low beam power ratting (Watts) is very easy. It is simply a matter of removing your old tungsten filament headlamps, installing new halogen headlamps, and plugging the headlamp connectors back in. You will get a very noticeable increase of light to drive by. Since you are not changing the power that your stock wiring harness carries you do not need to modify it. However to get the best light out of your new headlamps it would be a good time to check over your headlamp wiring connections. Converting to higher wattage halogen headlampsHigh power halogen lamps exceed the power handling capabilities of a stock LR wire harness and can cause damage to the harness and switches. You should rewire part of your headlamp harness and add a relay if you are planning to install high power halogen headlamps. High power halogen headlamps are normally labeled as high power on the box (if in doubt ask your sales person). The high power lamps usually have a low beam similar in power to the standard power halogen and tungsten filament lamps. The high power is usually reserved for the high beams. To safely use this kind of headlamp you need to put a relay in the high beam circuit to handle the additional power draw. You could leave the low beam circuit alone in this application or add a second relay to maximize power to the low beams while minimizing stress to the factory harness and light switch. There are some special high power lamps that are available that have high output on both high and low beams. This would require a relay on both the high beam circuit and the low beam circuit. If you get this kind of lamp be sure to get one that has a very sharp low bean cutoff so as not to blind oncoming traffic. IPF and Hella makes headlamps with sharp cutoff lenses. You will need to go out and purchase a relay if one did not come with the headlamps. Lucas makes a relay that is a rectangular metal can that works very well for this application and looks like it could have been factory stock. If you fell like a trip to your local wrecking yard, late 80's, early 90's Cadillacs have a group of three Bosch relays on the left inner wing that have triple water seals and potted leads. They are about as close to water proof as you are likely to find. Otherwise you can just get whatever your auto parts store offers. There is often a diagram of the relay's electrical connections etched on the side to tell you how to wire the relay.

Mount the relay(s) on the wing or radiator bulkhead somewhere near the horn in the front right corner. The Bosch relays from a Cadillac have a mounting bracket that you should get along with the relays. Find a place to get electricity. You may get it off the hot battery connector if your battery is mounted in the engine compartment or you can pull it from a main line. If you want to pull it off a main wire look for a solid brown wire. Solid brown designates always hot unfused main lead (disconnect the battery first). You will find a connection on the fuse block. You will want to connect a line fuse between where you pick up the electricity and the relay. Any wire between the main line and the fuse should be solid brown. Depending upon what kind of wire measuring system you are using the wire should be #12 AWG, or 44 strand. The stock wire harness has a blue with white stripe wire going from the foot switch to a 4 way connector in the upper right corner of the Land Rover just above the horn. There are three blue with a white stripe wires attached to the four way connector. This is your stock high beam system. You will use the wire coming from the foot switch to activate the relay and provide power to the other two wires (which are already 44 strand wires). If you are adding a low beam relay, the wire you want is blue/red. Looking at your relay there should be four connectors. They may have labels like S1, S2, R1, R2 or there may be a picture etched with corresponding connector designations. The connectors labeled S1 & S2 or shown on the diagram as a coil are the low power connections to the internal solenoid that activates the high power relay contacts. One of these connectors will take a black wire going to frame ground. The other gets connected to the blue white wire coming from the dimmer foot switch. It doesn't matter which of the S or solenoid terminal is which. Now, the brown wire to line fuse to blue wire goes to one of the R or relay contact terminals. Once again it doesn't matter which. Finally run a 44 strand (#12 AWG) blue with white stripe wire from the other R or relay terminal to the four way connector that has the two blue with white stripe wires going to the headlamps. And that is all there is to it. If I ever go to high power high beam headlamps that is how I would wire the connections. The fuse size depends upon the power your high beam draws so there is no firm number that I can provide. Since you have two high beam lamps divide two times the wattage of the high beam by 12 then add 25% as a fudge factor. Choose a fuse that is the closest higher current rating. One other thing. High power headlamps run a lot hotter than stock power headlamps. Be sure to turn them off when fording streams. Splashing cold water onto hot headlamps is likely to cause the headlamp lens to crack. Dim headlampsDim headlamps are often caused by oxidized or loose harness wiring. Connections will oxidize over time creating increased resistance. This will make your headlamps dimmer. So when you replace your headlamps it is a good idea to clean your wire connections and make sure that the headlamp harness is in good condition. And don't forget that halogen headlamps will not be as bright over time, so if your headlamps are several years old they just might be tired. The connectors that plug into the back of your headlamps are each part of a small three wire sub harness. If this sub harness has degraded new ones are readily available. The black wire will go to a ground connection on the underside of your radiator bulkhead. Make sure that all the connections are clean, including the connection between the ground connector and the metal of the bulkhead. A bad or high resistance ground connection is the most common cause of very dim headlamps. New Lucas ground connectors are readily available. The blue/white and blue/red wires each go to three way connectors near the horn. Check to make sure that the bullet connectors and the inside metal of the three way connectors are clean. New connectors are also readily available. Check the rubber gaskets where the wires pass through the radiator bulkhead and the headlamp bucket. Replace with new ones if the originals have deteriorated or are missing. These gaskets protect the insulation from abrasion and prevents shorts in your headlamp wiring. Check the connections to your hi-lo dimmer foot switch. It is probably a good idea to remove the foot switch, clean up the area and the connections. Once again check the rubber gasket where the wires go out through the kick panel. Open your instrument panel and check the connections to your headlamp switch. The wire going to the foot switch is the blue one. Once again you want a clean firm connection. This should provide you with bright headlamps. Don't forget to clean the head lamp lenses whenever you clean the windscreen. Dirt over the lenses can block out a lot of light and cause the headlamps to run warmer. |

|

If you would like to discuss any of the contents, or just say hi, please feel free to .

© 1997, 2001, 2017 TeriAnn Wakeman. All rights reserved. |